UV LED (Ultraviolet Light Emitting Diode) technology is a groundbreaking advancement in lighting, offering superior efficiency, precision, and versatility compared to traditional UV lamps. This comprehensive guide explores how UV LED lights work and their myriad benefits across various applications.

How UV LED Light Technology Works

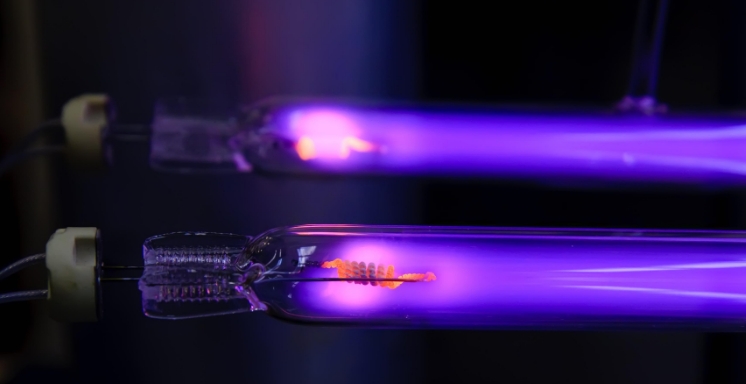

UV LED Light Technology

UV LED lights operate by converting electrical energy into ultraviolet light through a semiconductor diode. Unlike traditional UV lamps, which rely on gas discharge, UV LEDs use solid-state components. Here’s a breakdown of their working mechanism:

- Semiconductor Diode: The core of a UV LED is a diode made from materials like gallium nitride (GaN) or aluminum gallium nitride (AlGaN). These materials emit UV light when electrified.

- Wavelength Emission: The emitted light is controlled to specific UV wavelengths, such as 365nm or 395nm, which are commonly used in industrial and scientific applications.

- No Heat Radiation: Unlike traditional UV lamps, UV LEDs do not produce infrared light, making them energy-efficient and safer to use.

- On-Demand Operation: UV LEDs achieve full brightness instantly without requiring a warm-up period.

Benefits of UV LED Technology

| Feature | UV LEDs | Traditional UV Lamps |

|---|---|---|

| Energy Efficiency | Consumes up to 70% less power | Higher energy consumption |

| Lifespan | Up to 20,000-50,000 hours | Typically 5,000-10,000 hours |

| Wavelength Precision | Customizable to specific needs | Limited wavelength control |

| Safety | No mercury, minimal heat output | Contains mercury, emits heat |

| Durability | Solid-state, shock-resistant | Fragile glass construction |

| Environmental Impact | Eco-friendly and recyclable | Hazardous waste due to mercury |

Applications of UV LED Lights

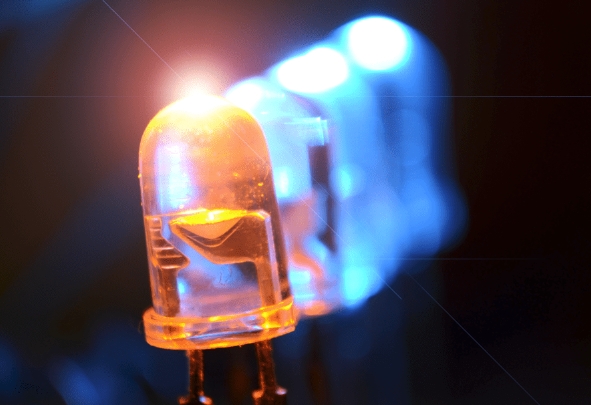

The core of a UV LED

UV LED technology has revolutionized various industries due to its precision and efficiency. Below are some of its key applications:

- Disinfection and Sterilization

UV LEDs destroy bacteria, viruses, and fungi by breaking down their DNA, making them vital for water purification, air sterilization, and surface disinfection. - Resin Curing

In manufacturing, UV LEDs are used to cure adhesives, inks, and coatings, delivering faster and more uniform results compared to traditional curing methods. - Printing and Inspection

UV LEDs are utilized in printing to dry inks and in inspection processes to detect defects or counterfeit items. - Forensics and Crime Scene Analysis

Their ability to reveal hidden evidence like fingerprints and body fluids makes UV LEDs indispensable in forensic science. - Gemstone and Mineral Identification

UV LEDs emit specific wavelengths that fluoresce minerals and gemstones, aiding in identification and quality assessment.

How to Choose the Right UV LED Light

Choose the Right UV LED Light

When selecting a UV LED light, consider the following factors:

| Criteria | Details |

|---|---|

| Wavelength | Choose 365nm for precise tasks like forensics or curing, and 395nm for general fluorescence. |

| Power Output | Higher wattage offers stronger illumination, ideal for industrial uses. |

| Durability | Ensure a robust design with water and impact resistance for long-term reliability. |

| Application | Select lights tailored to specific tasks like resin curing, disinfection, or inspection. |

Conclusion

UV LED light technology represents the future of ultraviolet applications, offering unmatched energy efficiency, precision, and environmental friendliness. By understanding how these lights work and their benefits, you can make informed decisions for your specific needs. Explore Tank007‘s range of UV LED lights today to experience the difference firsthand.