Non-Destructive Testing (NDT) plays a crucial role in industrial settings, ensuring safety and quality without damaging components. Among the tools used in NDT, UV flashlights are a preferred choice for their precision and efficiency.

Key Benefits of NDT UV Flashlights

1. Enhanced Defect Detection

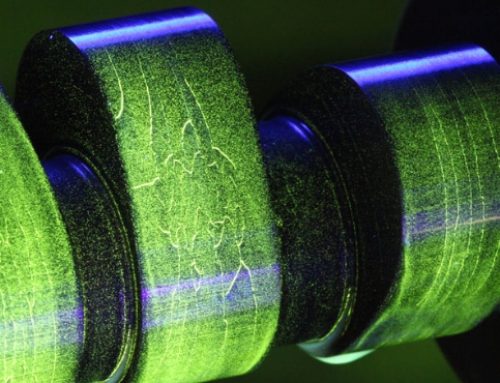

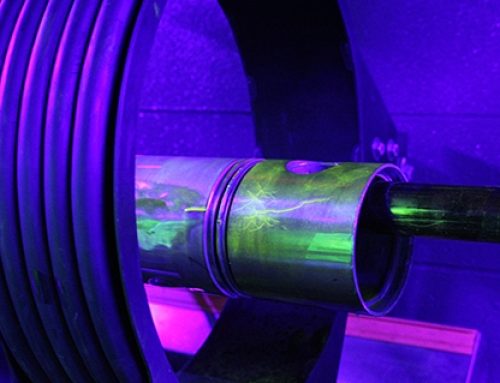

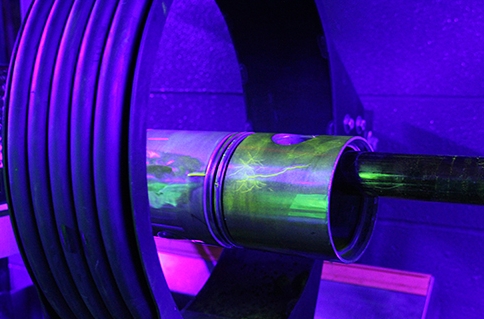

UV flashlights illuminate fluorescent penetrants applied to test surfaces, making even minute cracks or flaws highly visible.

- Example: Surface cracks in airplane components or pipelines that are invisible under normal lighting fluoresce brightly under UV light.

- Impact: Enhanced visibility ensures that defects are caught early, reducing risks.

2. Non-Destructive Process

NDT UV flashlights allow inspections without causing damage to the test material, preserving its usability and integrity.

- Compared to Destructive Testing: Unlike cutting or breaking components, UV-based NDT leaves them intact, saving costs.

3. Versatility Across Industries

NDT UV flashlights are applicable in diverse fields such as aerospace, automotive, oil and gas, and power generation.

- Use Cases:

- Detecting fatigue cracks in aircraft.

- Inspecting welds in pipelines.

- Ensuring structural integrity of bridges.

4. Compliance with Industry Standards

UV flashlights operate at specific wavelengths (usually 365 nm), meeting ASTM and ISO standards for industrial testing.

- Significance: Compliance ensures reliable and repeatable results, critical for safety-sensitive industries.

Comparison: NDT UV Flashlights vs. Other Inspection Tools

| Aspect | NDT UV Flashlights | Other Inspection Tools |

|---|---|---|

| Method | Uses fluorescence to detect defects. | May involve visual inspection or X-rays. |

| Damage Risk | Non-destructive, no material damage. | Some tools risk damaging test material. |

| Portability | Compact and lightweight, suitable for fieldwork. | Some are bulky and require stationary setups. |

| Cost | Cost-effective over time. | High upfront and operational costs. |

| Sensitivity | Detects microscopic cracks and flaws. | Sensitivity varies with method. |

Practical Applications of NDT UV Flashlights

1. Aerospace

- Purpose: Detect fatigue cracks, corrosion, and structural defects in aircraft parts.

- Benefit: Ensures safety and compliance with strict aviation standards.

2. Automotive

- Purpose: Inspect engine components, brake systems, and welds.

- Benefit: Improves vehicle reliability and performance.

3. Oil and Gas

- Purpose: Examine pipelines, storage tanks, and offshore platforms.

- Benefit: Prevents leaks and costly environmental disasters.

4. Power Plants

- Purpose: Inspect pressure vessels, turbines, and heat exchangers.

- Benefit: Enhances operational efficiency and reduces downtime.

Advantages of UV Flashlights in NDT

| Feature | Benefit |

|---|---|

| Compact Design | Easy to carry for field inspections in remote locations. |

| High-Intensity Beam | Ensures thorough inspection in low-light conditions. |

| Long Battery Life | Supports extended testing sessions without frequent recharging. |

| Uniform Illumination | Provides consistent UV light for accurate defect detection. |

| Durability | Withstands harsh industrial environments, including extreme temperatures. |

How NDT UV Flashlights Boost Efficiency

- Early Detection: Identifying defects early reduces costly repairs and downtime.

- Faster Inspections: The portability and ease of use speed up inspection processes.

- Improved Accuracy: High-intensity UV light ensures no defect goes unnoticed.

- Cost Savings: Non-destructive testing avoids material loss, making it economical over time.

Why Invest in Quality NDT UV Flashlights?

Using high-quality NDT UV flashlights ensures reliability, accuracy, and compliance with industry standards. Features like optimal UV wavelength, rugged construction, and long battery life are essential for industrial testing.

Tank007’s NDT UV flashlights are designed with professionals in mind, offering advanced features and exceptional durability to meet the demands of modern industries.

By integrating NDT UV flashlights into your inspection routine, you can enhance safety, boost efficiency, and ensure product integrity across various industrial applications.