The post NDT UV Flashlight Maintenance Tips and Tricks appeared first on Tank007.

]]>1. Why Maintenance is Crucial for NDT UV Flashlights

UV flashlights used in NDT are precision instruments. Regular maintenance:

- Ensures Accurate Inspections: Maintains consistent UV output for detecting defects.

- Extends Lifespan: Prevents premature failure of UV LEDs and batteries.

- Reduces Costs: Minimizes repair and replacement expenses.

2. Maintenance Checklist for NDT UV Flashlights

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect Lens and Filters | Before each use | Ensures clear UV transmission. |

| Clean UV Lens | Weekly | Removes dust and contaminants. |

| Check Battery Health | Monthly | Prevents power fluctuations affecting UV output. |

| Test UV Intensity | Quarterly | Ensures compliance with NDT standards. |

| Inspect Casing for Damage | After field inspections | Prevents water or dust ingress. |

| Calibrate UV Output (if applicable) | Annually | Maintains consistent UV intensity for accurate results. |

3. Detailed Maintenance Tips for NDT UV Flashlights

a. Cleaning the UV Lens and Filters

- Why: Dust and oil can reduce UV transmission, causing false or missed indications.

- How:

- Use a soft microfiber cloth slightly dampened with isopropyl alcohol.

- Gently wipe the lens in a circular motion.

- Avoid abrasive materials that could scratch the lens.

- Tip: Avoid touching the lens directly with fingers to prevent smudges.

b. Checking Battery Health

- Why: Power fluctuations can lead to inconsistent UV output.

- How:

- Use a multimeter to check voltage levels. Replace batteries if they drop below 80% of rated capacity.

- For rechargeable models, ensure proper charging cycles and avoid overcharging.

- Tip: Keep spare batteries during long inspections.

c. Inspecting the Casing for Damage

- Why: Cracks or gaps can allow dust or moisture to affect internal components.

- How:

- Check for cracks, especially around seals and buttons.

- Replace O-rings if they appear worn or brittle.

- Tip: Store flashlights in a protective case when not in use.

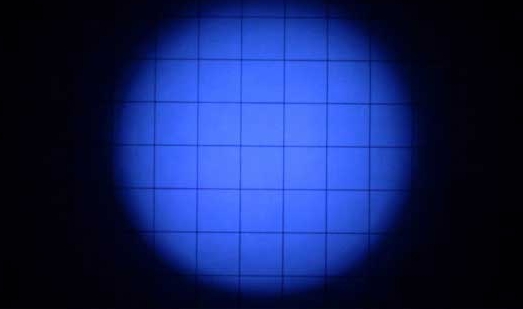

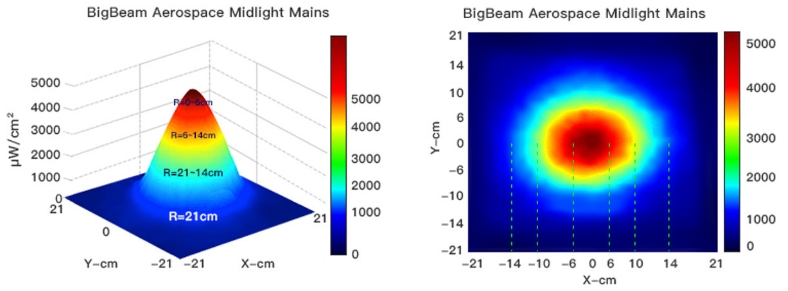

d. Testing UV Intensity

- Why: UV intensity below the required level may cause false negatives.

- How:

- Use a UV radiometer to measure output at a fixed distance (usually 15 inches).

- Ensure it meets the required NDT standard (often 1,000 μW/cm2).

- Tip: Keep a record of intensity tests for compliance audits.

4. Troubleshooting Common Issues

| Issue | Possible Cause | Solution |

|---|---|---|

| Dim UV Output | Low battery or dirty lens | Replace batteries, clean lens, and check LED connections. |

| Inconsistent UV Beam | Faulty power connection or LED degradation | Inspect wiring, replace damaged LEDs. |

| Flickering Light | Loose battery contacts or damaged switch | Tighten contacts, replace switch if needed. |

| Overheating | Blocked heat vents or prolonged use | Allow to cool, clean vents, reduce continuous usage time. |

| Moisture Inside Casing | Damaged seals or exposure to water | Replace O-rings, dry thoroughly, inspect for cracks. |

5. Comparison: Maintenance of Rechargeable vs. Disposable Battery UV Flashlights

| Aspect | Rechargeable Batteries | Disposable Batteries |

|---|---|---|

| Cost | Higher upfront cost, lower long-term cost | Lower upfront cost, higher long-term cost |

| Maintenance | Requires regular charging and cycle management | Replace batteries when drained, minimal maintenance |

| Lifespan | Longer if properly maintained | Limited by battery availability |

| Environmental Impact | Lower due to reusable nature | Higher due to disposable waste |

| Recommended For | Frequent users and professional inspections | Occasional users and emergency kits |

6. Best Practices for Storing UV Flashlights

- Keep in a Dry Environment: Prevents moisture-related damage.

- Use Protective Cases: Shields against dust and impacts.

- Store Batteries Separately: Reduces risk of corrosion inside the flashlight.

- Avoid Direct Sunlight: Prevents UV LED degradation and battery overheating.

7. Calibration Tips for NDT UV Flashlights

Why: Calibration ensures that UV output remains within standard levels, providing accurate NDT results.

How to Calibrate:

- Use a calibrated UV radiometer.

- Measure UV intensity at a standard distance (typically 15 inches).

- Adjust the flashlight’s settings if it has built-in calibration.

- Record calibration results and keep documentation for compliance.

Tip: Schedule calibration annually or after 500 hours of use.

8. Summary: Key Maintenance Tips

- Clean Regularly: Focus on lenses and filters.

- Test UV Intensity: Use a radiometer quarterly.

- Inspect for Damage: Check casing, seals, and buttons.

- Battery Care: Replace or recharge promptly.

Consistent maintenance not only extends the lifespan of your NDT UV flashlight but also ensures reliable and accurate inspections. Implement these tips to keep your equipment performing at its best!

The post NDT UV Flashlight Maintenance Tips and Tricks appeared first on Tank007.

]]>The post Common NDT Methods Enhanced by UV Flashlights appeared first on Tank007.

]]>1. Overview of Common NDT Methods Enhanced by UV Flashlights

| NDT Method | Primary Use | Role of UV Flashlight |

|---|---|---|

| Fluorescent Penetrant Testing (FPT) | Surface crack detection | Reveals fluorescent indications of cracks |

| Magnetic Particle Inspection (MPI) | Detects surface and near-surface defects in ferrous metals | Enhances visibility of magnetic particles |

| Leak Testing (Hydrostatic & Vacuum Testing) | Identifies leaks in sealed systems | Illuminates fluorescent dyes used to trace leaks |

| Radiographic Testing (RT) | Detects internal defects using X-rays | Assists in film interpretation with fluorescent markers |

| Visual Inspection (VT) | Surface-level defect detection | Enhances visibility with UV-sensitive materials |

2. How UV Flashlights Enhance NDT Methods

UV flashlights are effective due to their ability to excite fluorescent dyes and particles used in various NDT methods. The 365nm wavelength is ideal because it minimizes visible light interference, making fluorescent indications stand out more clearly. Below, we’ll break down how UV flashlights enhance each NDT method.

3. Detailed Comparison: NDT Methods Enhanced by UV Flashlights

| NDT Method | UV Wavelength | Common Applications | Effectiveness with UV Flashlight |

|---|---|---|---|

| Fluorescent Penetrant Testing (FPT) | 365nm | Aerospace, Automotive |      Enhances crack visibility Enhances crack visibility |

| Magnetic Particle Inspection (MPI) | 365nm | Welding, Pipelines |     Increases detection of fine cracks Increases detection of fine cracks |

| Leak Testing | 365nm | Storage Tanks, Valves |      Pinpoints even small leaks Pinpoints even small leaks |

| Radiographic Testing (RT) | 365nm | Pressure Vessels, Piping |    Assists in marker visibility Assists in marker visibility |

| Visual Inspection (VT) | 365nm | Surface Defect Detection |     Improves detection with UV-sensitive paints Improves detection with UV-sensitive paints |

4. Key NDT Methods Explained

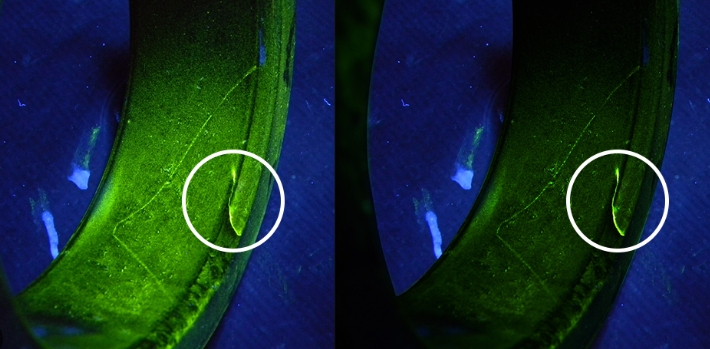

a. Fluorescent Penetrant Testing (FPT)

- Purpose: Detects surface cracks, seams, or porosity.

- Process: A fluorescent dye is applied to the surface, which penetrates cracks. Excess dye is removed, and a developer is applied to draw the dye out of defects. A UV flashlight then illuminates the area, revealing cracks as bright fluorescent lines.

- Advantages: High sensitivity and ability to detect fine cracks.

- Recommended UV Flashlight: TANK007 K9-A5 with 365nm wavelength for clear indications.

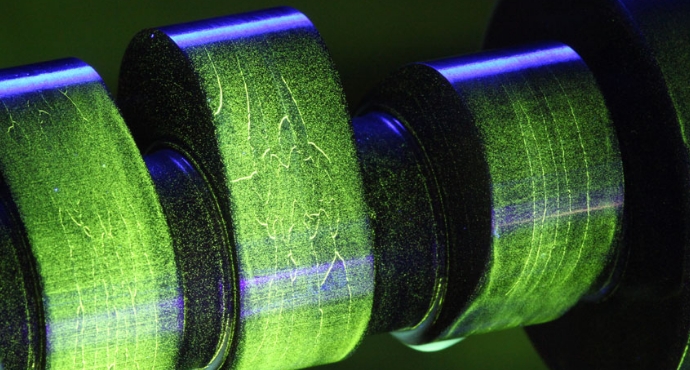

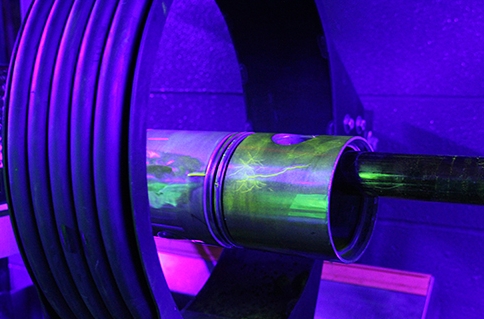

b. Magnetic Particle Inspection (MPI)

- Purpose: Identifies surface and near-surface flaws in ferrous materials.

- Process: A fluorescent magnetic powder is applied to a magnetized object. Defects disturb the magnetic field, causing particles to accumulate at flaw sites. UV flashlights highlight these accumulations.

- Advantages: Effective for weld inspections and pipelines.

- Recommended UV Flashlight: TANK007 UVC31 with high power for larger areas.

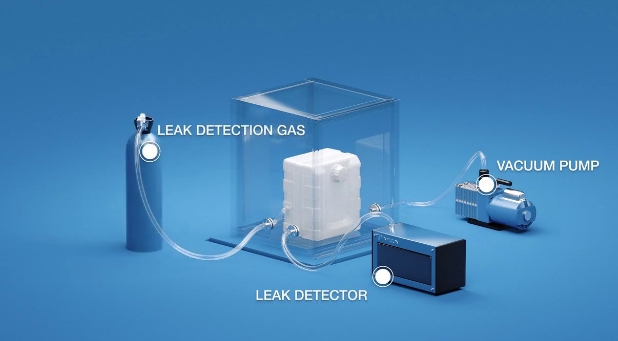

c. Leak Testing

- Purpose: Detects leaks in sealed systems like pipelines and tanks.

- Process: Fluorescent dyes are added to the system’s fluid. A UV flashlight is used to detect any traces of the dye leaking from the system.

- Advantages: Highly sensitive and precise.

- Recommended UV Flashlight: TANK007 UV01 for its portability and effectiveness in small-scale inspections.

5. Comparison of UV Flashlight Models for NDT

| Model | Wavelength | Power Source | Best For | Price Range |

|---|---|---|---|---|

| TANK007 K9-A5 | 365nm | USB Rechargeable | FPT and MPI (Mid-sized areas) | $30–$50 |

| TANK007 UV01 | 365nm | 1 AAA Battery | Leak Testing, Portable Inspections | $15–$25 |

| TANK007 UVC31 | 365nm | 18650 Rechargeable Battery | Large-scale MPI and Professional Use | $50–$70 |

6. Advantages of Using UV Flashlights in NDT

- Enhanced Detection: Makes fluorescent indications highly visible.

- Efficiency: Speeds up inspections with clear and bright indications.

- Safety: Allows detection without damaging the material.

- Versatility: Suitable for various NDT methods like FPT, MPI, and leak testing.

7. Tips for Choosing the Right UV Flashlight for NDT

- Wavelength: Ensure it is 365nm for optimal fluorescence.

- Power Source: Choose USB rechargeable for frequent use or battery-powered for occasional use.

- Brightness: Select higher lumens for large-scale or professional inspections.

8. Summary: Why Choose TANK007 for NDT?

- Specialized UV Flashlights: Designed specifically for NDT applications.

- Durability: Built with aircraft-grade aluminum and waterproof ratings.

- Cost-Effective: Offers models suitable for both professionals and occasional users.

Final Tip:

Choose TANK007 K9-A5 for balanced power, UV01 for budget and portability, and UVC31 for maximum power and professional use.

The post Common NDT Methods Enhanced by UV Flashlights appeared first on Tank007.

]]>The post Standards and Certifications for NDT UV Flashlights appeared first on Tank007.

]]>Importance of Standards in NDT UV Flashlights

Adherence to standards ensures:

- Consistent Performance: Guarantees that the flashlight delivers stable UV output at the specified wavelength.

- Reliability: Reduces the risk of missed flaws due to inadequate light quality.

- Safety Compliance: Ensures user safety during prolonged exposure.

- Industry Approval: Meets requirements for use in regulated industries like aerospace, automotive, and oil & gas.

Key Standards and Certifications

| Standard/Certification | Organization | Purpose | Key Requirements |

|---|---|---|---|

| ASTM E3022 | ASTM International | Specifies performance requirements for UV LED lamps used in NDT. | Minimum UV-A intensity, uniform beam distribution, and absence of visible light. |

| ISO 3059 | International Organization for Standardization | Defines requirements for viewing conditions in fluorescent penetrant and magnetic particle testing. | Ambient light levels, UV-A intensity at the workpiece, and eye safety considerations. |

| NADCAP | National Aerospace and Defense Contractors Accreditation Program | Establishes quality assurance standards for aerospace testing. | Certification of UV-A sources, traceability, and calibration procedures. |

| EN 1956 | European Standards (EN) | Specifies safety and performance criteria for UV lamps in penetrant testing. | UV intensity, uniformity, and permissible leakage of visible light. |

| CE Marking | European Union | Certifies that the product meets EU safety, health, and environmental protection standards. | Electrical safety, UV emission compliance, and labeling requirements. |

Detailed Comparison of Standards

| Feature | ASTM E3022 | ISO 3059 | NADCAP | EN 1956 | CE Marking |

|---|---|---|---|---|---|

| UV-A Intensity Range | 1,000–10,000 μW/cm2 | Minimum of 1,000 μW/cm2 | ≥1,200 μW/cm2 | ≥1,000 μW/cm2 | Meets EU safety norms. |

| Visible Light Leakage | ≤20 lux | ≤20 lux | ≤20 lux | ≤20 lux | Varies by application. |

| Beam Uniformity | Required | Not specified | Required | Required | Not specified. |

| Calibration Frequency | Annually recommended | Per user setup | Annually required | Annually required | Not applicable. |

| Industry Application | General NDT | Aerospace | Aerospace | General NDT | Cross-industry. |

Features of Certified NDT UV Flashlights

- UV-A Intensity: Certified flashlights provide precise UV-A output (365nm), ensuring adequate fluorescence of testing materials.

- Beam Uniformity: Reduces the risk of undetected defects in the inspection area.

- Durability: Rugged designs that withstand harsh industrial environments.

- Traceability: Certified models often come with serialized components for calibration tracking.

Tank007 Certified NDT UV Flashlights

Tank007 UVC31-NDT

- Compliance: ASTM E3022, ISO 3059.

- Specifications:

- Wavelength: 365nm with minimal visible light leakage.

- Intensity: Adjustable UV-A output for versatile applications.

- Build: Rugged and waterproof, designed for industrial environments.

- Certifications: CE marking, ensuring compliance with EU safety norms.

Learn more about the Tank007 UVC31-NDT here.

Checklist for Choosing a Certified UV Flashlight

- Check the Wavelength: Ensure it emits UV-A light (365nm) with minimal visible light.

- Verify Compliance: Look for certifications like ASTM E3022, ISO 3059, or EN 1956.

- Beam Uniformity: Ensure uniform light distribution for accurate inspections.

- Durability and Portability: Rugged, lightweight designs for easy handling.

- Calibration Support: Availability of calibration services or in-built calibration tools.

Benefits of Using Certified NDT UV Flashlights

- Enhanced Accuracy: Precise UV-A output ensures reliable flaw detection.

- Compliance with Regulations: Avoid penalties in regulated industries by using certified equipment.

- Improved Safety: Reduced exposure to harmful UV or visible light.

- Cost-Efficiency: Certified flashlights last longer and require minimal maintenance.

Conclusion

Understanding and adhering to NDT standards like ASTM E3022 and ISO 3059 is critical for ensuring the quality, reliability, and safety of UV flashlights. Certified flashlights, such as the Tank007 UVC31-NDT, offer unparalleled performance, making them a valuable investment for professionals across industries.

By selecting a certified flashlight, you not only comply with industry regulations but also enhance inspection efficiency and accuracy, ultimately safeguarding material integrity.

The post Standards and Certifications for NDT UV Flashlights appeared first on Tank007.

]]>The post Comparing NDT UV Flashlights: LED vs. Traditional Bulb appeared first on Tank007.

]]>Introduction to NDT UV Flashlights

UV flashlights in NDT work by illuminating a surface with ultraviolet light to highlight defects when used with fluorescent penetrants or magnetic particles. The choice between LED and traditional bulb flashlights can significantly impact inspection efficiency and accuracy.

Key Features of LED and Traditional Bulb UV Flashlights

| Feature | LED UV Flashlights | Traditional Bulb UV Flashlights |

|---|---|---|

| Light Source | Light-emitting diodes (LEDs) with a precise wavelength. | Mercury vapor or fluorescent bulbs. |

| Wavelength Stability | Highly stable and consistent. | May vary as the bulb ages or due to temperature changes. |

| Lifespan | Up to 50,000 hours. | 1,000-2,000 hours on average. |

| Energy Efficiency | Highly energy-efficient, consuming less power. | Consumes more power, generating significant heat. |

| Durability | Shockproof and robust design. | Fragile, prone to damage from impacts. |

| Cost | Higher initial cost but lower long-term costs. | Lower upfront cost but higher maintenance expenses. |

Advantages and Disadvantages

LED UV Flashlights

Advantages:

- Efficiency: Consumes less energy, reducing battery usage.

- Lifespan: Longer operational life, minimizing replacement frequency.

- Portability: Compact and lightweight for field inspections.

- Performance: Stable UV output, ensuring consistent inspection results.

Disadvantages:

- Higher upfront cost compared to traditional bulb flashlights.

- Limited to specific wavelengths, typically around 365nm.

Traditional Bulb UV Flashlights

Advantages:

- Lower initial cost, making them accessible for budget-constrained operations.

- Broad-spectrum UV light, suitable for diverse applications.

Disadvantages:

- Shorter lifespan, requiring frequent bulb replacements.

- Bulky and less portable.

- Emits more heat, potentially impacting user comfort and safety.

Applications of LED vs. Traditional Bulb UV Flashlights

| Industry | Preferred Flashlight | Reason |

|---|---|---|

| Aerospace | LED UV Flashlight | Consistent results in critical inspections. |

| Automotive | LED UV Flashlight | Portability and durability for on-site checks. |

| Oil & Gas | LED UV Flashlight | Reliable in harsh environments. |

| Education/Training | Traditional Bulb UV Flashlight | Lower cost for non-intensive use. |

| General Inspection | Depends on budget and needs | Budget may favor traditional; precision favors LED. |

Performance Comparison: LED vs. Traditional Bulb

| Metric | LED UV Flashlight | Traditional Bulb UV Flashlight |

|---|---|---|

| UV Intensity | High and consistent. | May decrease over time. |

| Heat Emission | Minimal, safe for prolonged use. | Significant, can be uncomfortable. |

| Inspection Area | Focused, precise beams. | Broader, less concentrated light. |

| Cost Efficiency | High over the long term. | High maintenance and operating costs. |

| Eco-Friendliness | Environmentally friendly. | Contains hazardous mercury. |

Case Study: Tank007 UVC31-NDT

The Tank007 UVC31-NDT UV flashlight leverages advanced LED technology for professional-grade NDT inspections:

- Wavelength: Stable 365nm UV output for reliable defect detection.

- Lifespan: Over 50,000 hours of operation, reducing long-term costs.

- Durability: Shockproof and water-resistant, ideal for industrial use.

Learn more about Tank007 UVC31-NDT here.

Tips for Selecting the Right UV Flashlight for NDT

- Determine Your Budget: LED flashlights are cost-effective over time but require higher upfront investment.

- Assess Durability Needs: For fieldwork, choose a rugged, shockproof model.

- Prioritize Consistency: LED flashlights ensure stable UV output for precise results.

- Consider Applications: For large-scale inspections, traditional bulbs may provide broader coverage, but LEDs excel in precision tasks.

Conclusion

Both LED and traditional bulb UV flashlights have their merits in NDT. While LED UV flashlights are preferred for their efficiency, durability, and precision, traditional bulb UV flashlights can be suitable for budget-friendly or broad-spectrum applications. For professionals seeking reliability and long-term value, investing in a high-quality LED model like the Tank007 UVC31-NDT is highly recommended.

By understanding the key differences and aligning them with your specific needs, you can ensure optimal inspection performance and cost-efficiency.

The post Comparing NDT UV Flashlights: LED vs. Traditional Bulb appeared first on Tank007.

]]>The post Top Industries That Use NDT UV Flashlights appeared first on Tank007.

]]>What Are NDT UV Flashlights?

NDT UV flashlights emit ultraviolet light, typically at a wavelength of 365nm, ideal for fluorescence-based inspections. These flashlights are used with penetrants or magnetic particles to highlight defects that are invisible to the naked eye.

Top Industries Using NDT UV Flashlights

| Industry | Applications | Key Benefits |

|---|---|---|

| Aerospace | Inspection of aircraft components, engine parts, and fuselages. | Ensures safety and compliance with stringent regulations. |

| Automotive | Examination of welds, castings, and engine components. | Detects defects that could lead to critical failures. |

| Oil & Gas | Inspection of pipelines, storage tanks, and offshore rigs. | Prevents leaks, corrosion, and structural failures. |

| Construction | Assessment of bridges, buildings, and structural welds. | Extends lifespan and ensures safety of infrastructure. |

| Power Generation | Inspection of turbines, boilers, and nuclear reactor components. | Maintains operational efficiency and safety. |

| Railways | Examination of rail tracks, wheels, and bogies for cracks and defects. | Reduces the risk of accidents and downtime. |

| Defense & Military | Inspection of weapon systems, vehicles, and aircraft. | Enhances reliability in critical missions. |

| Manufacturing | Quality control of products, including metal parts, plastics, and composites. | Improves product quality and reduces waste. |

How UV Flashlights Are Used in NDT

- Fluorescent Penetrant Testing (FPT):

A liquid penetrant is applied to the test surface, followed by a developer. The UV flashlight highlights cracks and defects where the penetrant has seeped in. - Magnetic Particle Inspection (MPI):

Magnetic particles are applied to a magnetized test piece. The UV light reveals defects by illuminating the magnetic particles gathered around cracks.

Choosing the Right NDT UV Flashlight

| Feature | Importance | Recommendation |

|---|---|---|

| Wavelength | 365nm is ideal for NDT as it provides optimal fluorescence visibility. | Tank007 UVC31-NDT UV Flashlight. |

| Power Output | High-power UV flashlights allow for better visibility in larger inspection areas. | Choose models with at least 3W power for professional use. |

| Durability | Rugged, waterproof, and shockproof designs are essential for industrial environments. | Look for flashlights with robust construction. |

| Battery Life | Longer battery life ensures uninterrupted inspections in the field. | Prefer flashlights with rechargeable batteries. |

| Portability | Lightweight and compact designs are ideal for field inspections. | Compact models are better for on-the-go inspections. |

Comparison of NDT UV Flashlights

| Model | Wavelength | Power Output | Applications | Price Range |

|---|---|---|---|---|

| Tank007 UVC31-NDT | 365nm | 3W | Aerospace, oil & gas, defense. | $$$ |

| Generic NDT Flashlight | 395nm | 1-2W | Hobbyist or entry-level applications. | $$ |

| Industrial NDT UV Light | 365nm | 5W | Heavy-duty industrial inspections. | $$$$ |

Case Studies: Industry Use of NDT UV Flashlights

Aerospace

An aviation company used the Tank007 UVC31-NDT UV flashlight to inspect turbine blades for cracks:

- Detected micro-cracks invisible to traditional methods.

- Reduced maintenance time by 30%.

- Enhanced safety compliance.

Oil & Gas

An offshore rig operator utilized a high-powered UV flashlight for pipeline inspections:

- Identified corrosion early, saving thousands in repair costs.

- Improved safety by preventing potential leaks.

Future Trends in NDT UV Flashlight Applications

- Integration with AI:

AI-powered analysis combined with UV inspections could provide automated defect detection. - Wearable UV Inspection Tools:

Hands-free devices like headlamps with UV functionality for improved efficiency. - Advanced Materials Testing:

Broader applications in composites and advanced materials used in aerospace and defense.

Conclusion

NDT UV flashlights are indispensable in industries where safety and quality are paramount. Choosing the right flashlight, such as the Tank007 UVC31-NDT, tailored to your industry’s needs ensures reliable and efficient inspections.

By understanding the unique requirements of your field, investing in quality tools, and staying updated with technological advancements, industries can achieve superior quality assurance and operational safety.

The post Top Industries That Use NDT UV Flashlights appeared first on Tank007.

]]>The post UV Light for NDT Testing: Key Considerations for Quality Assurance appeared first on Tank007.

]]>Why Use UV Light in NDT?

UV light enhances visibility by activating fluorescent materials applied during PT and MT. Defects like cracks, pores, and material inconsistencies become visible under a UV light at 365 nm, the standard wavelength for NDT applications.

Key Considerations When Choosing a UV Light for NDT

| Factor | Explanation | Recommendation |

|---|---|---|

| Wavelength | 365 nm is the standard for fluorescent inspections. | Use 365 nm UV flashlights like Tank007 UVC31-NDT. |

| Intensity | UV lights should meet intensity standards (≥1,000 μW/cm2). | Ensure UV light intensity meets ASTM E3022. |

| Beam Uniformity | A uniform beam prevents missed areas and ensures consistent inspection results. | Select UV lights with optical uniformity. |

| Durability | NDT environments often include harsh conditions such as oil, dust, and chemicals. | Choose rugged models like the Tank007 UVC31-NDT. |

| Portability | Lightweight, portable UV lights are ideal for fieldwork. | Opt for compact designs with battery operation. |

Step-by-Step Guide to Using UV Light for NDT

- Prepare the Inspection Area:

- Eliminate ambient light using dark curtains or enclosures.

- Set Up the UV Light:

- Verify intensity with a UV radiometer.

- Position the UV light at the recommended distance (usually 15 inches).

- Apply Inspection Materials:

- PT: Apply the penetrant, allow dwell time, and remove excess material.

- MT: Apply magnetic particles and a magnetic field to the test surface.

- Inspect for Indications:

- Switch to UV light, scan the surface, and observe fluorescent indications.

- Document Findings:

- Record defects for further analysis and reporting.

- Clean the Surface:

- Remove any remaining materials to maintain cleanliness.

Comparison of NDT UV Flashlights

| Model | Wavelength (nm) | Intensity (μW/cm2) | Beam Type | Weight (g) | Best For |

|---|---|---|---|---|---|

| Tank007 UVC31-NDT | 365 | 12,000 | Uniform | 180 | Comprehensive PT and MT inspections. |

| Model X | 365 | 10,000 | Adjustable Beam | 210 | Large-scale field inspections. |

| Model Y | 370 | 8,000 | Focused Beam | 190 | Precision inspection in small areas. |

Advantages of the Tank007 UVC31-NDT

The Tank007 UVC31-NDT is designed specifically for NDT applications. Key features include:

- 365 nm Wavelength: Perfect for fluorescent penetrant and magnetic particle testing.

- High Intensity: Uniform light projection at 12,000 μW/cm2 for precise defect detection.

- Durable Design: Water-resistant and robust, ideal for industrial environments.

- Compact Portability: Lightweight and easy to use in the field.

Explore the UVC31-NDT flashlight: Tank007 UVC31-NDT.

Investing in a quality UV flashlight like the Tank007 UVC31-NDT enhances accuracy and reliability in NDT testing. Choose the best for your quality assurance needs!

The post UV Light for NDT Testing: Key Considerations for Quality Assurance appeared first on Tank007.

]]>The post Step-by-Step Guide to Using NDT UV Flashlights for Fluorescent Testing appeared first on Tank007.

]]>Non-Destructive Testing (NDT) using UV flashlights plays a critical role in detecting surface and subsurface defects in industrial materials without causing damage. This guide provides a step-by-step process for effectively using NDT UV flashlights in fluorescent testing, highlighting best practices, safety measures, and technical details.

1. Understanding Fluorescent Testing in NDT

Fluorescent Testing is a method where materials are inspected under ultraviolet (UV) light after being coated with a fluorescent dye penetrant. When exposed to UV light, these dyes emit bright fluorescent colors, revealing cracks, fractures, or other defects.

Key Advantages:

- Non-invasive testing method.

- Accurate detection of surface and near-surface defects.

- Applicable in various industries (Aerospace, Automotive, Manufacturing).

2. Equipment Required for Fluorescent Testing

| Equipment | Description |

|---|---|

| NDT UV Flashlight | High-intensity UV light source (365 nm). |

| Fluorescent Dye Penetrant | Liquid dye for defect highlighting. |

| Cleaner/Remover | Removes excess penetrant. |

| Developer Spray | Enhances defect visibility. |

| Safety Gear | UV goggles, gloves, protective clothing. |

3. Step-by-Step Guide to Using NDT UV Flashlights

Step 1: Surface Preparation

- Objective: Ensure the surface is clean and free from contaminants.

- Actions:

- Use a cleaner to remove oil, grease, and dust.

- Ensure the surface is dry before applying the dye.

Step 2: Apply Fluorescent Dye Penetrant

- Objective: Allow the dye to penetrate surface defects.

- Actions:

- Evenly apply the fluorescent dye on the surface.

- Let it sit for the recommended dwell time (usually 10–30 minutes).

Step 3: Remove Excess Penetrant

- Objective: Avoid background fluorescence that could obscure results.

- Actions:

- Wipe off excess penetrant using a clean cloth.

- Avoid over-cleaning, as it may remove penetrant from defects.

Step 4: Apply Developer

- Objective: Draw penetrant from defects to the surface.

- Actions:

- Spray developer evenly over the surface.

- Allow sufficient time for the developer to act (5–10 minutes).

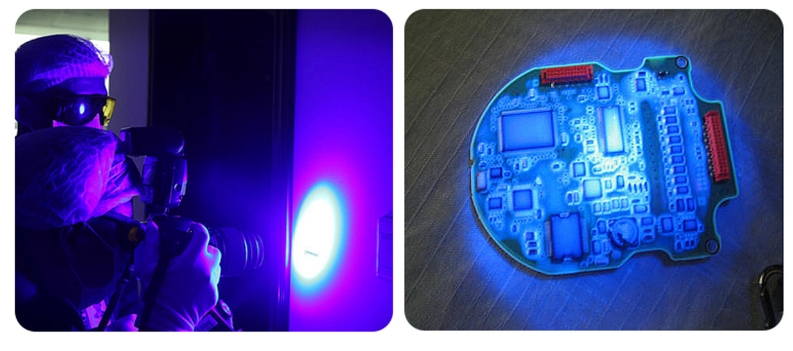

Step 5: UV Light Inspection

- Objective: Identify and evaluate defects under UV light.

- Actions:

- Darken the inspection area to reduce ambient light.

- Turn on the NDT UV flashlight (365 nm wavelength).

- Scan the surface systematically.

- Look for bright fluorescent indications that suggest cracks or defects.

Step 6: Record and Analyze Findings

- Objective: Document defects for reporting and analysis.

- Actions:

- Photograph and mark detected defects.

- Record the type, size, and location of each defect.

4. Comparison of NDT UV Flashlights vs. Standard Flashlights

| Feature | NDT UV Flashlight | Standard Flashlight |

|---|---|---|

| Wavelength | 365 nm (optimal for NDT) | 400+ nm (ineffective) |

| Light Intensity | High-intensity UV output | General illumination |

| Fluorescence Detection | Yes | No |

| Application | Industrial inspections | General-purpose lighting |

5. Safety Precautions

- Always wear UV-blocking goggles to protect your eyes.

- Avoid direct skin exposure to UV light for prolonged periods.

- Ensure proper ventilation when using chemical penetrants.

- Follow manufacturer guidelines for each piece of equipment.

6. Best Practices for Effective Fluorescent Testing

- Maintain consistent distance between the flashlight and the inspection surface.

- Ensure the UV flashlight has stable power output.

- Regularly calibrate UV equipment for accuracy.

- Use low ambient light conditions during inspections.

7. Real-World Application Example

Scenario: Aerospace Component Testing

- Component: Aircraft engine turbine blades

- Method: Fluorescent penetrant testing with NDT UV flashlight

- Findings: Micro-cracks detected on critical load-bearing areas

- Outcome: Defective parts replaced before critical failure

8. Conclusion

Using NDT UV flashlights for fluorescent testing is an essential and highly effective method for identifying surface and near-surface defects. By following this step-by-step guide, inspectors can ensure consistent results, improved safety, and higher reliability in their inspections.

Explore Tank007’s Range of NDT UV Flashlights for Precision Testing!

The post Step-by-Step Guide to Using NDT UV Flashlights for Fluorescent Testing appeared first on Tank007.

]]>The post How to Choose the Right NDT UV Flashlight for Your Needs appeared first on Tank007.

]]>Key Considerations When Choosing an NDT UV Flashlight

1. Wavelength of UV Light

The wavelength of UV light emitted by the flashlight determines the level of visibility and the types of defects it can highlight. For NDT applications, a UV flashlight with a wavelength between 365 nm and 405 nm is generally recommended.

- 365 nm: Commonly used for detecting surface cracks, leaks, and defects in critical applications. Ideal for materials that require higher sensitivity.

- 405 nm: Offers broader coverage and is effective for general-purpose inspections. Slightly less sensitive than 365 nm.

Wavelength Comparison Table

| Wavelength | Recommended Use | Pros | Cons |

|---|---|---|---|

| 365 nm | Critical NDT applications (aerospace, automotive, etc.) | Detects finer cracks and defects, higher sensitivity | May not work well with all penetrants |

| 385 nm | General-purpose inspection | Broader coverage, works with many standard penetrants | Lower sensitivity compared to 365 nm |

| 405 nm | Basic NDT tasks, surface-level inspections | Longer battery life, works on many materials | Less sensitive, may miss small defects |

2. Light Intensity (UV Power)

The light intensity of an NDT UV flashlight impacts how clearly you can view defects in various lighting conditions. The higher the light intensity, the clearer and brighter the defect appears under UV light. However, higher intensity also means faster battery drain.

- High-intensity flashlights: Ideal for inspections in challenging environments, such as outdoors or in large areas.

- Medium-intensity flashlights: Suitable for standard inspections with moderate battery usage.

- Low-intensity flashlights: Good for smaller or indoor areas with minimal lighting interference.

Light Intensity Comparison Table

| Intensity | Recommended Use | Pros | Cons |

|---|---|---|---|

| High | Outdoor inspections, large structures | Bright, penetrates materials easily | Faster battery consumption |

| Medium | Standard industrial applications | Balanced performance and battery life | May not be sufficient in bright environments |

| Low | Indoor inspections or small components | Longer battery life, sufficient for detailed work | Less effective in bright or large areas |

3. Durability and Build Quality

Industrial environments often present challenging conditions such as dust, water, and impact. A durable UV flashlight ensures longevity and reliable performance even under harsh conditions. Look for features like:

- Waterproof: IP65 or higher ratings for protection against water and dust.

- Shockproof: Designed to withstand drops or impacts, which is essential for on-site inspections.

- Temperature resistance: Ability to function in extreme hot or cold conditions.

Durability Rating Comparison

| Rating | Description | Recommended Use |

|---|---|---|

| IP65 | Dust-tight and protected against water jets | General industrial use, moderate conditions |

| IP67 | Fully dust-tight and can withstand immersion up to 1 meter | Harsh outdoor environments, heavy industrial use |

| IP68 | Fully dust-tight and protected from continuous submersion | Extreme conditions, underwater inspections (e.g., marine) |

4. Battery Life and Power Source

Long battery life is critical to minimize downtime and improve efficiency during inspections. Flashlights with rechargeable lithium-ion batteries are popular due to their extended life and high performance. When choosing a flashlight, consider:

- Rechargeable batteries: More cost-effective in the long run.

- Disposable batteries: Convenient for short-term use, but can be expensive over time.

- Battery life: Ideally, a flashlight should last for several hours on a single charge, depending on its intensity setting.

Battery Life Comparison

| Battery Type | Charging Time | Battery Life (per charge) | Recommended Use |

|---|---|---|---|

| Lithium-ion | 2-4 hours | 3-8 hours (depending on intensity) | Regular inspections, long battery life |

| AA Alkaline | N/A | 1-4 hours | Short-term use, low budget options |

| NiMH Rechargeable | 2-3 hours | 2-6 hours | Eco-friendly, cost-effective in the long term |

5. Industry Standards (ASTM E3022)

When choosing an NDT UV flashlight, it is essential to ensure that the flashlight meets industry standards, such as ASTM E3022, which outlines the minimum performance requirements for UV inspection flashlights. Compliance with these standards ensures reliable and repeatable results.

- ASTM E3022-18: Establishes the requirements for UV flashlights used in the inspection of materials, including intensity, wavelength, and beam uniformity.

- ISO 3059: Describes the test methods for UV inspection flashlights used in NDT applications.

A flashlight that adheres to these standards will ensure that your testing is accurate, repeatable, and compliant with industry regulations.

Conclusion: Choosing the Right NDT UV Flashlight for Your Needs

Selecting the right NDT UV flashlight involves considering several factors such as wavelength, light intensity, durability, battery life, and industry standards. Whether you’re inspecting aerospace components, pipelines, or automotive parts, it is important to choose a flashlight that meets the demands of your specific application.

Tank007 offers high-quality NDT UV flashlights that comply with ASTM E3022 standards, providing reliable, durable, and efficient performance. With adjustable intensity, various wavelength options, and long-lasting battery life, Tank007 flashlights are designed to meet the diverse needs of NDT professionals.

The post How to Choose the Right NDT UV Flashlight for Your Needs appeared first on Tank007.

]]>The post Benefits of Using NDT UV Flashlights in Industrial Testing appeared first on Tank007.

]]>Key Benefits of NDT UV Flashlights

1. Enhanced Defect Detection

UV flashlights illuminate fluorescent penetrants applied to test surfaces, making even minute cracks or flaws highly visible.

- Example: Surface cracks in airplane components or pipelines that are invisible under normal lighting fluoresce brightly under UV light.

- Impact: Enhanced visibility ensures that defects are caught early, reducing risks.

2. Non-Destructive Process

NDT UV flashlights allow inspections without causing damage to the test material, preserving its usability and integrity.

- Compared to Destructive Testing: Unlike cutting or breaking components, UV-based NDT leaves them intact, saving costs.

3. Versatility Across Industries

NDT UV flashlights are applicable in diverse fields such as aerospace, automotive, oil and gas, and power generation.

- Use Cases:

- Detecting fatigue cracks in aircraft.

- Inspecting welds in pipelines.

- Ensuring structural integrity of bridges.

4. Compliance with Industry Standards

UV flashlights operate at specific wavelengths (usually 365 nm), meeting ASTM and ISO standards for industrial testing.

- Significance: Compliance ensures reliable and repeatable results, critical for safety-sensitive industries.

Comparison: NDT UV Flashlights vs. Other Inspection Tools

| Aspect | NDT UV Flashlights | Other Inspection Tools |

|---|---|---|

| Method | Uses fluorescence to detect defects. | May involve visual inspection or X-rays. |

| Damage Risk | Non-destructive, no material damage. | Some tools risk damaging test material. |

| Portability | Compact and lightweight, suitable for fieldwork. | Some are bulky and require stationary setups. |

| Cost | Cost-effective over time. | High upfront and operational costs. |

| Sensitivity | Detects microscopic cracks and flaws. | Sensitivity varies with method. |

Practical Applications of NDT UV Flashlights

1. Aerospace

- Purpose: Detect fatigue cracks, corrosion, and structural defects in aircraft parts.

- Benefit: Ensures safety and compliance with strict aviation standards.

2. Automotive

- Purpose: Inspect engine components, brake systems, and welds.

- Benefit: Improves vehicle reliability and performance.

3. Oil and Gas

- Purpose: Examine pipelines, storage tanks, and offshore platforms.

- Benefit: Prevents leaks and costly environmental disasters.

4. Power Plants

- Purpose: Inspect pressure vessels, turbines, and heat exchangers.

- Benefit: Enhances operational efficiency and reduces downtime.

Advantages of UV Flashlights in NDT

| Feature | Benefit |

|---|---|

| Compact Design | Easy to carry for field inspections in remote locations. |

| High-Intensity Beam | Ensures thorough inspection in low-light conditions. |

| Long Battery Life | Supports extended testing sessions without frequent recharging. |

| Uniform Illumination | Provides consistent UV light for accurate defect detection. |

| Durability | Withstands harsh industrial environments, including extreme temperatures. |

How NDT UV Flashlights Boost Efficiency

- Early Detection: Identifying defects early reduces costly repairs and downtime.

- Faster Inspections: The portability and ease of use speed up inspection processes.

- Improved Accuracy: High-intensity UV light ensures no defect goes unnoticed.

- Cost Savings: Non-destructive testing avoids material loss, making it economical over time.

Why Invest in Quality NDT UV Flashlights?

Using high-quality NDT UV flashlights ensures reliability, accuracy, and compliance with industry standards. Features like optimal UV wavelength, rugged construction, and long battery life are essential for industrial testing.

Tank007’s NDT UV flashlights are designed with professionals in mind, offering advanced features and exceptional durability to meet the demands of modern industries.

By integrating NDT UV flashlights into your inspection routine, you can enhance safety, boost efficiency, and ensure product integrity across various industrial applications.

The post Benefits of Using NDT UV Flashlights in Industrial Testing appeared first on Tank007.

]]>The post What is an NDT UV Flashlight and How It Works? appeared first on Tank007.

]]>What is an NDT UV Flashlight?

An NDT UV flashlight is a specialized ultraviolet light tool used in fluorescent inspection processes within non-destructive testing. It emits UV-A light in the wavelength range of 320–400 nanometers, which is ideal for activating fluorescent dyes or coatings applied to materials. When these dyes are exposed to UV light, they fluoresce brightly, revealing cracks, leaks, or other imperfections that are invisible to the naked eye.

How Does an NDT UV Flashlight Work?

The working principle of an NDT UV flashlight is based on fluorescence. Here’s a breakdown:

- Surface Preparation: The material surface is cleaned and treated with a fluorescent penetrant or dye.

- Penetrant Application: The dye is applied and allowed to seep into any surface cracks or flaws.

- Excess Removal: Excess dye is removed, leaving only the penetrant in the flaws.

- Inspection with UV Light: The NDT UV flashlight illuminates the surface. Flaws appear as bright fluorescent lines or spots under the UV light.

Applications of NDT UV Flashlights

- Aerospace: Inspection of aircraft parts for fatigue cracks.

- Automotive: Quality control of components like engine blocks.

- Oil and Gas: Pipeline and tank inspection for corrosion or leakage.

- Power Plants: Examination of pressure vessels and turbines.

Key Features of NDT UV Flashlights

| Feature | Description | Importance |

|---|---|---|

| UV Wavelength | 365 nm is the industry standard. | Provides optimal fluorescence of dyes. |

| Beam Uniformity | Consistent UV beam without hotspots. | Ensures even illumination for accurate inspection. |

| Light Intensity | Typically measured in microwatts/cm2. | High intensity ensures better visibility of flaws. |

| Battery Life | Long-lasting rechargeable batteries. | Reduces downtime during inspections. |

| Portability | Compact and lightweight design. | Easy to handle in confined spaces. |

Types of NDT UV Flashlights

| Type | Description | Recommended Use |

|---|---|---|

| Handheld UV Flashlights | Compact and portable with high-intensity UV light. | General NDT inspections in various industries. |

| Stationary UV Lamps | Larger devices for covering broader areas. | Ideal for labs or large-scale inspections. |

| Rechargeable UV Lights | Environmentally friendly, cost-effective models. | Frequent use in remote locations. |

| Waterproof UV Lights | Designed to resist moisture and harsh environments. | Suitable for oil, gas, and marine applications. |

Advantages of Using NDT UV Flashlights

- Non-Invasive: Detects flaws without damaging the material.

- High Sensitivity: Reveals even microscopic defects.

- Cost-Effective: Reduces downtime by identifying issues early.

- Versatile Applications: Can be used across various industries and materials.

How to Choose the Right NDT UV Flashlight?

When selecting an NDT UV flashlight, consider:

- Wavelength Compliance: Ensure it emits UV-A light at 365 nm.

- Intensity Standards: Meets or exceeds ASTM and ISO standards.

- Durability: Built for rugged industrial environments.

- Portability: Lightweight and ergonomic for ease of use.

- Certification: Look for certifications like CE or RoHS for quality assurance.

Conclusion

The NDT UV flashlight is a cornerstone tool in non-destructive testing, enabling professionals to detect imperfections with precision and reliability. By choosing the right flashlight and using it effectively, industries can maintain safety, ensure quality, and minimize operational risks.

Investing in high-quality NDT UV flashlights like those offered by Tank007 can enhance your inspection processes and deliver exceptional results.

The post What is an NDT UV Flashlight and How It Works? appeared first on Tank007.

]]>