The post NDT UV Flashlight Maintenance Tips and Tricks appeared first on Tank007.

]]>1. Why Maintenance is Crucial for NDT UV Flashlights

UV flashlights used in NDT are precision instruments. Regular maintenance:

- Ensures Accurate Inspections: Maintains consistent UV output for detecting defects.

- Extends Lifespan: Prevents premature failure of UV LEDs and batteries.

- Reduces Costs: Minimizes repair and replacement expenses.

2. Maintenance Checklist for NDT UV Flashlights

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect Lens and Filters | Before each use | Ensures clear UV transmission. |

| Clean UV Lens | Weekly | Removes dust and contaminants. |

| Check Battery Health | Monthly | Prevents power fluctuations affecting UV output. |

| Test UV Intensity | Quarterly | Ensures compliance with NDT standards. |

| Inspect Casing for Damage | After field inspections | Prevents water or dust ingress. |

| Calibrate UV Output (if applicable) | Annually | Maintains consistent UV intensity for accurate results. |

3. Detailed Maintenance Tips for NDT UV Flashlights

a. Cleaning the UV Lens and Filters

- Why: Dust and oil can reduce UV transmission, causing false or missed indications.

- How:

- Use a soft microfiber cloth slightly dampened with isopropyl alcohol.

- Gently wipe the lens in a circular motion.

- Avoid abrasive materials that could scratch the lens.

- Tip: Avoid touching the lens directly with fingers to prevent smudges.

b. Checking Battery Health

- Why: Power fluctuations can lead to inconsistent UV output.

- How:

- Use a multimeter to check voltage levels. Replace batteries if they drop below 80% of rated capacity.

- For rechargeable models, ensure proper charging cycles and avoid overcharging.

- Tip: Keep spare batteries during long inspections.

c. Inspecting the Casing for Damage

- Why: Cracks or gaps can allow dust or moisture to affect internal components.

- How:

- Check for cracks, especially around seals and buttons.

- Replace O-rings if they appear worn or brittle.

- Tip: Store flashlights in a protective case when not in use.

d. Testing UV Intensity

- Why: UV intensity below the required level may cause false negatives.

- How:

- Use a UV radiometer to measure output at a fixed distance (usually 15 inches).

- Ensure it meets the required NDT standard (often 1,000 μW/cm2).

- Tip: Keep a record of intensity tests for compliance audits.

4. Troubleshooting Common Issues

| Issue | Possible Cause | Solution |

|---|---|---|

| Dim UV Output | Low battery or dirty lens | Replace batteries, clean lens, and check LED connections. |

| Inconsistent UV Beam | Faulty power connection or LED degradation | Inspect wiring, replace damaged LEDs. |

| Flickering Light | Loose battery contacts or damaged switch | Tighten contacts, replace switch if needed. |

| Overheating | Blocked heat vents or prolonged use | Allow to cool, clean vents, reduce continuous usage time. |

| Moisture Inside Casing | Damaged seals or exposure to water | Replace O-rings, dry thoroughly, inspect for cracks. |

5. Comparison: Maintenance of Rechargeable vs. Disposable Battery UV Flashlights

| Aspect | Rechargeable Batteries | Disposable Batteries |

|---|---|---|

| Cost | Higher upfront cost, lower long-term cost | Lower upfront cost, higher long-term cost |

| Maintenance | Requires regular charging and cycle management | Replace batteries when drained, minimal maintenance |

| Lifespan | Longer if properly maintained | Limited by battery availability |

| Environmental Impact | Lower due to reusable nature | Higher due to disposable waste |

| Recommended For | Frequent users and professional inspections | Occasional users and emergency kits |

6. Best Practices for Storing UV Flashlights

- Keep in a Dry Environment: Prevents moisture-related damage.

- Use Protective Cases: Shields against dust and impacts.

- Store Batteries Separately: Reduces risk of corrosion inside the flashlight.

- Avoid Direct Sunlight: Prevents UV LED degradation and battery overheating.

7. Calibration Tips for NDT UV Flashlights

Why: Calibration ensures that UV output remains within standard levels, providing accurate NDT results.

How to Calibrate:

- Use a calibrated UV radiometer.

- Measure UV intensity at a standard distance (typically 15 inches).

- Adjust the flashlight’s settings if it has built-in calibration.

- Record calibration results and keep documentation for compliance.

Tip: Schedule calibration annually or after 500 hours of use.

8. Summary: Key Maintenance Tips

- Clean Regularly: Focus on lenses and filters.

- Test UV Intensity: Use a radiometer quarterly.

- Inspect for Damage: Check casing, seals, and buttons.

- Battery Care: Replace or recharge promptly.

Consistent maintenance not only extends the lifespan of your NDT UV flashlight but also ensures reliable and accurate inspections. Implement these tips to keep your equipment performing at its best!

The post NDT UV Flashlight Maintenance Tips and Tricks appeared first on Tank007.

]]>The post Standards and Certifications for NDT UV Flashlights appeared first on Tank007.

]]>Importance of Standards in NDT UV Flashlights

Adherence to standards ensures:

- Consistent Performance: Guarantees that the flashlight delivers stable UV output at the specified wavelength.

- Reliability: Reduces the risk of missed flaws due to inadequate light quality.

- Safety Compliance: Ensures user safety during prolonged exposure.

- Industry Approval: Meets requirements for use in regulated industries like aerospace, automotive, and oil & gas.

Key Standards and Certifications

| Standard/Certification | Organization | Purpose | Key Requirements |

|---|---|---|---|

| ASTM E3022 | ASTM International | Specifies performance requirements for UV LED lamps used in NDT. | Minimum UV-A intensity, uniform beam distribution, and absence of visible light. |

| ISO 3059 | International Organization for Standardization | Defines requirements for viewing conditions in fluorescent penetrant and magnetic particle testing. | Ambient light levels, UV-A intensity at the workpiece, and eye safety considerations. |

| NADCAP | National Aerospace and Defense Contractors Accreditation Program | Establishes quality assurance standards for aerospace testing. | Certification of UV-A sources, traceability, and calibration procedures. |

| EN 1956 | European Standards (EN) | Specifies safety and performance criteria for UV lamps in penetrant testing. | UV intensity, uniformity, and permissible leakage of visible light. |

| CE Marking | European Union | Certifies that the product meets EU safety, health, and environmental protection standards. | Electrical safety, UV emission compliance, and labeling requirements. |

Detailed Comparison of Standards

| Feature | ASTM E3022 | ISO 3059 | NADCAP | EN 1956 | CE Marking |

|---|---|---|---|---|---|

| UV-A Intensity Range | 1,000–10,000 μW/cm2 | Minimum of 1,000 μW/cm2 | ≥1,200 μW/cm2 | ≥1,000 μW/cm2 | Meets EU safety norms. |

| Visible Light Leakage | ≤20 lux | ≤20 lux | ≤20 lux | ≤20 lux | Varies by application. |

| Beam Uniformity | Required | Not specified | Required | Required | Not specified. |

| Calibration Frequency | Annually recommended | Per user setup | Annually required | Annually required | Not applicable. |

| Industry Application | General NDT | Aerospace | Aerospace | General NDT | Cross-industry. |

Features of Certified NDT UV Flashlights

- UV-A Intensity: Certified flashlights provide precise UV-A output (365nm), ensuring adequate fluorescence of testing materials.

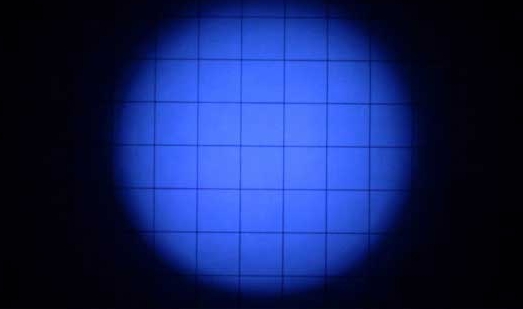

- Beam Uniformity: Reduces the risk of undetected defects in the inspection area.

- Durability: Rugged designs that withstand harsh industrial environments.

- Traceability: Certified models often come with serialized components for calibration tracking.

Tank007 Certified NDT UV Flashlights

Tank007 UVC31-NDT

- Compliance: ASTM E3022, ISO 3059.

- Specifications:

- Wavelength: 365nm with minimal visible light leakage.

- Intensity: Adjustable UV-A output for versatile applications.

- Build: Rugged and waterproof, designed for industrial environments.

- Certifications: CE marking, ensuring compliance with EU safety norms.

Learn more about the Tank007 UVC31-NDT here.

Checklist for Choosing a Certified UV Flashlight

- Check the Wavelength: Ensure it emits UV-A light (365nm) with minimal visible light.

- Verify Compliance: Look for certifications like ASTM E3022, ISO 3059, or EN 1956.

- Beam Uniformity: Ensure uniform light distribution for accurate inspections.

- Durability and Portability: Rugged, lightweight designs for easy handling.

- Calibration Support: Availability of calibration services or in-built calibration tools.

Benefits of Using Certified NDT UV Flashlights

- Enhanced Accuracy: Precise UV-A output ensures reliable flaw detection.

- Compliance with Regulations: Avoid penalties in regulated industries by using certified equipment.

- Improved Safety: Reduced exposure to harmful UV or visible light.

- Cost-Efficiency: Certified flashlights last longer and require minimal maintenance.

Conclusion

Understanding and adhering to NDT standards like ASTM E3022 and ISO 3059 is critical for ensuring the quality, reliability, and safety of UV flashlights. Certified flashlights, such as the Tank007 UVC31-NDT, offer unparalleled performance, making them a valuable investment for professionals across industries.

By selecting a certified flashlight, you not only comply with industry regulations but also enhance inspection efficiency and accuracy, ultimately safeguarding material integrity.

The post Standards and Certifications for NDT UV Flashlights appeared first on Tank007.

]]>The post Comparing NDT UV Flashlights: LED vs. Traditional Bulb appeared first on Tank007.

]]>Introduction to NDT UV Flashlights

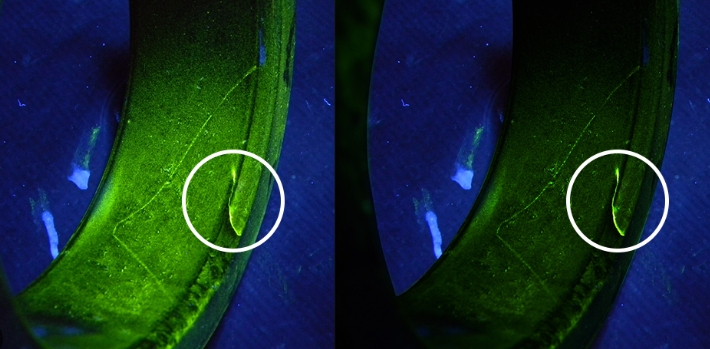

UV flashlights in NDT work by illuminating a surface with ultraviolet light to highlight defects when used with fluorescent penetrants or magnetic particles. The choice between LED and traditional bulb flashlights can significantly impact inspection efficiency and accuracy.

Key Features of LED and Traditional Bulb UV Flashlights

| Feature | LED UV Flashlights | Traditional Bulb UV Flashlights |

|---|---|---|

| Light Source | Light-emitting diodes (LEDs) with a precise wavelength. | Mercury vapor or fluorescent bulbs. |

| Wavelength Stability | Highly stable and consistent. | May vary as the bulb ages or due to temperature changes. |

| Lifespan | Up to 50,000 hours. | 1,000-2,000 hours on average. |

| Energy Efficiency | Highly energy-efficient, consuming less power. | Consumes more power, generating significant heat. |

| Durability | Shockproof and robust design. | Fragile, prone to damage from impacts. |

| Cost | Higher initial cost but lower long-term costs. | Lower upfront cost but higher maintenance expenses. |

Advantages and Disadvantages

LED UV Flashlights

Advantages:

- Efficiency: Consumes less energy, reducing battery usage.

- Lifespan: Longer operational life, minimizing replacement frequency.

- Portability: Compact and lightweight for field inspections.

- Performance: Stable UV output, ensuring consistent inspection results.

Disadvantages:

- Higher upfront cost compared to traditional bulb flashlights.

- Limited to specific wavelengths, typically around 365nm.

Traditional Bulb UV Flashlights

Advantages:

- Lower initial cost, making them accessible for budget-constrained operations.

- Broad-spectrum UV light, suitable for diverse applications.

Disadvantages:

- Shorter lifespan, requiring frequent bulb replacements.

- Bulky and less portable.

- Emits more heat, potentially impacting user comfort and safety.

Applications of LED vs. Traditional Bulb UV Flashlights

| Industry | Preferred Flashlight | Reason |

|---|---|---|

| Aerospace | LED UV Flashlight | Consistent results in critical inspections. |

| Automotive | LED UV Flashlight | Portability and durability for on-site checks. |

| Oil & Gas | LED UV Flashlight | Reliable in harsh environments. |

| Education/Training | Traditional Bulb UV Flashlight | Lower cost for non-intensive use. |

| General Inspection | Depends on budget and needs | Budget may favor traditional; precision favors LED. |

Performance Comparison: LED vs. Traditional Bulb

| Metric | LED UV Flashlight | Traditional Bulb UV Flashlight |

|---|---|---|

| UV Intensity | High and consistent. | May decrease over time. |

| Heat Emission | Minimal, safe for prolonged use. | Significant, can be uncomfortable. |

| Inspection Area | Focused, precise beams. | Broader, less concentrated light. |

| Cost Efficiency | High over the long term. | High maintenance and operating costs. |

| Eco-Friendliness | Environmentally friendly. | Contains hazardous mercury. |

Case Study: Tank007 UVC31-NDT

The Tank007 UVC31-NDT UV flashlight leverages advanced LED technology for professional-grade NDT inspections:

- Wavelength: Stable 365nm UV output for reliable defect detection.

- Lifespan: Over 50,000 hours of operation, reducing long-term costs.

- Durability: Shockproof and water-resistant, ideal for industrial use.

Learn more about Tank007 UVC31-NDT here.

Tips for Selecting the Right UV Flashlight for NDT

- Determine Your Budget: LED flashlights are cost-effective over time but require higher upfront investment.

- Assess Durability Needs: For fieldwork, choose a rugged, shockproof model.

- Prioritize Consistency: LED flashlights ensure stable UV output for precise results.

- Consider Applications: For large-scale inspections, traditional bulbs may provide broader coverage, but LEDs excel in precision tasks.

Conclusion

Both LED and traditional bulb UV flashlights have their merits in NDT. While LED UV flashlights are preferred for their efficiency, durability, and precision, traditional bulb UV flashlights can be suitable for budget-friendly or broad-spectrum applications. For professionals seeking reliability and long-term value, investing in a high-quality LED model like the Tank007 UVC31-NDT is highly recommended.

By understanding the key differences and aligning them with your specific needs, you can ensure optimal inspection performance and cost-efficiency.

The post Comparing NDT UV Flashlights: LED vs. Traditional Bulb appeared first on Tank007.

]]>The post UV Light for NDT Testing: Key Considerations for Quality Assurance appeared first on Tank007.

]]>Why Use UV Light in NDT?

UV light enhances visibility by activating fluorescent materials applied during PT and MT. Defects like cracks, pores, and material inconsistencies become visible under a UV light at 365 nm, the standard wavelength for NDT applications.

Key Considerations When Choosing a UV Light for NDT

| Factor | Explanation | Recommendation |

|---|---|---|

| Wavelength | 365 nm is the standard for fluorescent inspections. | Use 365 nm UV flashlights like Tank007 UVC31-NDT. |

| Intensity | UV lights should meet intensity standards (≥1,000 μW/cm2). | Ensure UV light intensity meets ASTM E3022. |

| Beam Uniformity | A uniform beam prevents missed areas and ensures consistent inspection results. | Select UV lights with optical uniformity. |

| Durability | NDT environments often include harsh conditions such as oil, dust, and chemicals. | Choose rugged models like the Tank007 UVC31-NDT. |

| Portability | Lightweight, portable UV lights are ideal for fieldwork. | Opt for compact designs with battery operation. |

Step-by-Step Guide to Using UV Light for NDT

- Prepare the Inspection Area:

- Eliminate ambient light using dark curtains or enclosures.

- Set Up the UV Light:

- Verify intensity with a UV radiometer.

- Position the UV light at the recommended distance (usually 15 inches).

- Apply Inspection Materials:

- PT: Apply the penetrant, allow dwell time, and remove excess material.

- MT: Apply magnetic particles and a magnetic field to the test surface.

- Inspect for Indications:

- Switch to UV light, scan the surface, and observe fluorescent indications.

- Document Findings:

- Record defects for further analysis and reporting.

- Clean the Surface:

- Remove any remaining materials to maintain cleanliness.

Comparison of NDT UV Flashlights

| Model | Wavelength (nm) | Intensity (μW/cm2) | Beam Type | Weight (g) | Best For |

|---|---|---|---|---|---|

| Tank007 UVC31-NDT | 365 | 12,000 | Uniform | 180 | Comprehensive PT and MT inspections. |

| Model X | 365 | 10,000 | Adjustable Beam | 210 | Large-scale field inspections. |

| Model Y | 370 | 8,000 | Focused Beam | 190 | Precision inspection in small areas. |

Advantages of the Tank007 UVC31-NDT

The Tank007 UVC31-NDT is designed specifically for NDT applications. Key features include:

- 365 nm Wavelength: Perfect for fluorescent penetrant and magnetic particle testing.

- High Intensity: Uniform light projection at 12,000 μW/cm2 for precise defect detection.

- Durable Design: Water-resistant and robust, ideal for industrial environments.

- Compact Portability: Lightweight and easy to use in the field.

Explore the UVC31-NDT flashlight: Tank007 UVC31-NDT.

Investing in a quality UV flashlight like the Tank007 UVC31-NDT enhances accuracy and reliability in NDT testing. Choose the best for your quality assurance needs!

The post UV Light for NDT Testing: Key Considerations for Quality Assurance appeared first on Tank007.

]]>The post Top 10 NDT (Non-Destructive Testing) UV flashlight manufacturers appeared first on Tank007.

]]>Top 10 NDT (Non-Destructive Testing) UV flashlight manufacturers

SGS

| Established Time | 1878 |

| Headquarters location | Geneva, Switzerland |

| Website | www.sgs.com |

SGS: A pioneer in global inspection services, SGS delivers a wide range of NDT solutions including radiographic, ultrasonic, and visual inspections. Their use of advanced NDT UV flashlights ensures precise flaw detection during fluorescent penetrant testing.

Applus+

| Established Time | 1996 |

| Headquarters location | Barcelona, Spain |

| Website | www.applus.com |

Applus+: Specializing in aerospace and oil & gas industries, Applus+ excels in ultrasonic and phased array inspections. NDT UV flashlights enhance their dye penetrant and magnetic particle testing methods for surface defect identification.

Bureau Veritas

| Established Time | 1828 |

| Headquarters location | Neuilly-sur-Seine, France |

| Website | www.bureauveritas.com |

Bureau Veritas: Known for their expertise in quality assurance, Bureau Veritas offers cutting-edge acoustic emission and thermography NDT services. UV flashlights are integral to their fluorescent inspection processes.

Intertek

| Established Time | 1888 |

| Headquarters location | London, UK |

| Website | www.intertek.com |

Intertek: With a focus on material integrity, Intertek integrates NDT UV flashlights into their penetrant testing procedures to ensure seamless flaw detection in metals and composites.

TüV Rheinland

| Established Time | 1872 |

| Headquarters location | Cologne, Germany |

| Website | www.tuv.com |

TüV Rheinland: TüV Rheinland is a global leader in NDT services such as eddy current and magnetic particle inspections. Their use of UV flashlights guarantees high precision in surface and weld testing.

Mistras Group

| Established Time | 1978 |

| Headquarters location | NJ, USA |

| Website | www.mistrasgroup.com |

Mistras Group: Providing both traditional and innovative NDT solutions, Mistras Group uses UV flashlights for dye penetrant inspections, ensuring reliability in industries like energy and transportation.

Acuren Inspection

| Established Time | 1974 |

| Headquarters location | NB, Canada |

| Website | www.acuren.com |

Acuren Inspection: Acuren offers a comprehensive suite of NDT services, focusing on visual and ultrasonic testing. Their use of NDT UV flashlights ensures accurate crack detection in pipelines and structures.

Olympus

| Established Time | 1919 |

| Headquarters location | MA, USA |

| Website | www.olympus-ims.com |

Olympus: Olympus is a leading provider of inspection tools, offering ultrasonic and phased array systems. Their NDT UV flashlights enhance their testing tools for more effective flaw detection.

Zetec

| Established Time | 1968 |

| Headquarters location | WA, USA |

| Website | www.zetec.com |

Zetec: Zetec is renowned for its advanced eddy current and ultrasonic solutions. Their UV flashlights are indispensable for enhancing the accuracy of dye penetrant testing across industries.

Magnaflux

| Established Time | 1938 |

| Headquarters location | IL, USA |

| Website | www.magnaflux.com |

Magnaflux: A market leader in magnetic particle and dye penetrant testing, Magnaflux utilizes NDT UV flashlights for high-quality fluorescent inspections in manufacturing and aerospace.

The post Top 10 NDT (Non-Destructive Testing) UV flashlight manufacturers appeared first on Tank007.

]]>