The post Step-by-Step Guide to Using NDT UV Flashlights for Fluorescent Testing appeared first on Tank007.

]]>Non-Destructive Testing (NDT) using UV flashlights plays a critical role in detecting surface and subsurface defects in industrial materials without causing damage. This guide provides a step-by-step process for effectively using NDT UV flashlights in fluorescent testing, highlighting best practices, safety measures, and technical details.

1. Understanding Fluorescent Testing in NDT

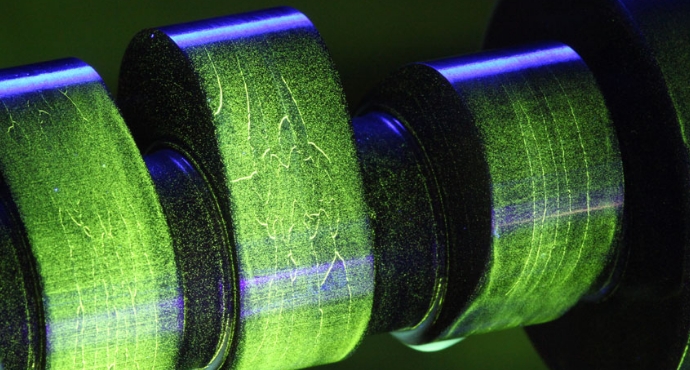

Fluorescent Testing is a method where materials are inspected under ultraviolet (UV) light after being coated with a fluorescent dye penetrant. When exposed to UV light, these dyes emit bright fluorescent colors, revealing cracks, fractures, or other defects.

Key Advantages:

- Non-invasive testing method.

- Accurate detection of surface and near-surface defects.

- Applicable in various industries (Aerospace, Automotive, Manufacturing).

2. Equipment Required for Fluorescent Testing

| Equipment | Description |

|---|---|

| NDT UV Flashlight | High-intensity UV light source (365 nm). |

| Fluorescent Dye Penetrant | Liquid dye for defect highlighting. |

| Cleaner/Remover | Removes excess penetrant. |

| Developer Spray | Enhances defect visibility. |

| Safety Gear | UV goggles, gloves, protective clothing. |

3. Step-by-Step Guide to Using NDT UV Flashlights

Step 1: Surface Preparation

- Objective: Ensure the surface is clean and free from contaminants.

- Actions:

- Use a cleaner to remove oil, grease, and dust.

- Ensure the surface is dry before applying the dye.

Step 2: Apply Fluorescent Dye Penetrant

- Objective: Allow the dye to penetrate surface defects.

- Actions:

- Evenly apply the fluorescent dye on the surface.

- Let it sit for the recommended dwell time (usually 10–30 minutes).

Step 3: Remove Excess Penetrant

- Objective: Avoid background fluorescence that could obscure results.

- Actions:

- Wipe off excess penetrant using a clean cloth.

- Avoid over-cleaning, as it may remove penetrant from defects.

Step 4: Apply Developer

- Objective: Draw penetrant from defects to the surface.

- Actions:

- Spray developer evenly over the surface.

- Allow sufficient time for the developer to act (5–10 minutes).

Step 5: UV Light Inspection

- Objective: Identify and evaluate defects under UV light.

- Actions:

- Darken the inspection area to reduce ambient light.

- Turn on the NDT UV flashlight (365 nm wavelength).

- Scan the surface systematically.

- Look for bright fluorescent indications that suggest cracks or defects.

Step 6: Record and Analyze Findings

- Objective: Document defects for reporting and analysis.

- Actions:

- Photograph and mark detected defects.

- Record the type, size, and location of each defect.

4. Comparison of NDT UV Flashlights vs. Standard Flashlights

| Feature | NDT UV Flashlight | Standard Flashlight |

|---|---|---|

| Wavelength | 365 nm (optimal for NDT) | 400+ nm (ineffective) |

| Light Intensity | High-intensity UV output | General illumination |

| Fluorescence Detection | Yes | No |

| Application | Industrial inspections | General-purpose lighting |

5. Safety Precautions

- Always wear UV-blocking goggles to protect your eyes.

- Avoid direct skin exposure to UV light for prolonged periods.

- Ensure proper ventilation when using chemical penetrants.

- Follow manufacturer guidelines for each piece of equipment.

6. Best Practices for Effective Fluorescent Testing

- Maintain consistent distance between the flashlight and the inspection surface.

- Ensure the UV flashlight has stable power output.

- Regularly calibrate UV equipment for accuracy.

- Use low ambient light conditions during inspections.

7. Real-World Application Example

Scenario: Aerospace Component Testing

- Component: Aircraft engine turbine blades

- Method: Fluorescent penetrant testing with NDT UV flashlight

- Findings: Micro-cracks detected on critical load-bearing areas

- Outcome: Defective parts replaced before critical failure

8. Conclusion

Using NDT UV flashlights for fluorescent testing is an essential and highly effective method for identifying surface and near-surface defects. By following this step-by-step guide, inspectors can ensure consistent results, improved safety, and higher reliability in their inspections.

Explore Tank007’s Range of NDT UV Flashlights for Precision Testing!

The post Step-by-Step Guide to Using NDT UV Flashlights for Fluorescent Testing appeared first on Tank007.

]]>The post How to Choose the Right NDT UV Flashlight for Your Needs appeared first on Tank007.

]]>Key Considerations When Choosing an NDT UV Flashlight

1. Wavelength of UV Light

The wavelength of UV light emitted by the flashlight determines the level of visibility and the types of defects it can highlight. For NDT applications, a UV flashlight with a wavelength between 365 nm and 405 nm is generally recommended.

- 365 nm: Commonly used for detecting surface cracks, leaks, and defects in critical applications. Ideal for materials that require higher sensitivity.

- 405 nm: Offers broader coverage and is effective for general-purpose inspections. Slightly less sensitive than 365 nm.

Wavelength Comparison Table

| Wavelength | Recommended Use | Pros | Cons |

|---|---|---|---|

| 365 nm | Critical NDT applications (aerospace, automotive, etc.) | Detects finer cracks and defects, higher sensitivity | May not work well with all penetrants |

| 385 nm | General-purpose inspection | Broader coverage, works with many standard penetrants | Lower sensitivity compared to 365 nm |

| 405 nm | Basic NDT tasks, surface-level inspections | Longer battery life, works on many materials | Less sensitive, may miss small defects |

2. Light Intensity (UV Power)

The light intensity of an NDT UV flashlight impacts how clearly you can view defects in various lighting conditions. The higher the light intensity, the clearer and brighter the defect appears under UV light. However, higher intensity also means faster battery drain.

- High-intensity flashlights: Ideal for inspections in challenging environments, such as outdoors or in large areas.

- Medium-intensity flashlights: Suitable for standard inspections with moderate battery usage.

- Low-intensity flashlights: Good for smaller or indoor areas with minimal lighting interference.

Light Intensity Comparison Table

| Intensity | Recommended Use | Pros | Cons |

|---|---|---|---|

| High | Outdoor inspections, large structures | Bright, penetrates materials easily | Faster battery consumption |

| Medium | Standard industrial applications | Balanced performance and battery life | May not be sufficient in bright environments |

| Low | Indoor inspections or small components | Longer battery life, sufficient for detailed work | Less effective in bright or large areas |

3. Durability and Build Quality

Industrial environments often present challenging conditions such as dust, water, and impact. A durable UV flashlight ensures longevity and reliable performance even under harsh conditions. Look for features like:

- Waterproof: IP65 or higher ratings for protection against water and dust.

- Shockproof: Designed to withstand drops or impacts, which is essential for on-site inspections.

- Temperature resistance: Ability to function in extreme hot or cold conditions.

Durability Rating Comparison

| Rating | Description | Recommended Use |

|---|---|---|

| IP65 | Dust-tight and protected against water jets | General industrial use, moderate conditions |

| IP67 | Fully dust-tight and can withstand immersion up to 1 meter | Harsh outdoor environments, heavy industrial use |

| IP68 | Fully dust-tight and protected from continuous submersion | Extreme conditions, underwater inspections (e.g., marine) |

4. Battery Life and Power Source

Long battery life is critical to minimize downtime and improve efficiency during inspections. Flashlights with rechargeable lithium-ion batteries are popular due to their extended life and high performance. When choosing a flashlight, consider:

- Rechargeable batteries: More cost-effective in the long run.

- Disposable batteries: Convenient for short-term use, but can be expensive over time.

- Battery life: Ideally, a flashlight should last for several hours on a single charge, depending on its intensity setting.

Battery Life Comparison

| Battery Type | Charging Time | Battery Life (per charge) | Recommended Use |

|---|---|---|---|

| Lithium-ion | 2-4 hours | 3-8 hours (depending on intensity) | Regular inspections, long battery life |

| AA Alkaline | N/A | 1-4 hours | Short-term use, low budget options |

| NiMH Rechargeable | 2-3 hours | 2-6 hours | Eco-friendly, cost-effective in the long term |

5. Industry Standards (ASTM E3022)

When choosing an NDT UV flashlight, it is essential to ensure that the flashlight meets industry standards, such as ASTM E3022, which outlines the minimum performance requirements for UV inspection flashlights. Compliance with these standards ensures reliable and repeatable results.

- ASTM E3022-18: Establishes the requirements for UV flashlights used in the inspection of materials, including intensity, wavelength, and beam uniformity.

- ISO 3059: Describes the test methods for UV inspection flashlights used in NDT applications.

A flashlight that adheres to these standards will ensure that your testing is accurate, repeatable, and compliant with industry regulations.

Conclusion: Choosing the Right NDT UV Flashlight for Your Needs

Selecting the right NDT UV flashlight involves considering several factors such as wavelength, light intensity, durability, battery life, and industry standards. Whether you’re inspecting aerospace components, pipelines, or automotive parts, it is important to choose a flashlight that meets the demands of your specific application.

Tank007 offers high-quality NDT UV flashlights that comply with ASTM E3022 standards, providing reliable, durable, and efficient performance. With adjustable intensity, various wavelength options, and long-lasting battery life, Tank007 flashlights are designed to meet the diverse needs of NDT professionals.

The post How to Choose the Right NDT UV Flashlight for Your Needs appeared first on Tank007.

]]>