Non-Destructive Testing (NDT) is a critical process in industries like aerospace, manufacturing, and oil & gas to detect defects without damaging the material. Among various NDT techniques, UV flashlights, especially those emitting at 365nm, play a significant role in enhancing the accuracy and efficiency of these tests. In this article, we will explore the most common NDT methods where UV flashlights are indispensable, compare their effectiveness, and provide insights on selecting the right UV flashlight.

1. Overview of Common NDT Methods Enhanced by UV Flashlights

| NDT Method | Primary Use | Role of UV Flashlight |

|---|---|---|

| Fluorescent Penetrant Testing (FPT) | Surface crack detection | Reveals fluorescent indications of cracks |

| Magnetic Particle Inspection (MPI) | Detects surface and near-surface defects in ferrous metals | Enhances visibility of magnetic particles |

| Leak Testing (Hydrostatic & Vacuum Testing) | Identifies leaks in sealed systems | Illuminates fluorescent dyes used to trace leaks |

| Radiographic Testing (RT) | Detects internal defects using X-rays | Assists in film interpretation with fluorescent markers |

| Visual Inspection (VT) | Surface-level defect detection | Enhances visibility with UV-sensitive materials |

2. How UV Flashlights Enhance NDT Methods

UV flashlights are effective due to their ability to excite fluorescent dyes and particles used in various NDT methods. The 365nm wavelength is ideal because it minimizes visible light interference, making fluorescent indications stand out more clearly. Below, we’ll break down how UV flashlights enhance each NDT method.

3. Detailed Comparison: NDT Methods Enhanced by UV Flashlights

| NDT Method | UV Wavelength | Common Applications | Effectiveness with UV Flashlight |

|---|---|---|---|

| Fluorescent Penetrant Testing (FPT) | 365nm | Aerospace, Automotive | ????? Enhances crack visibility |

| Magnetic Particle Inspection (MPI) | 365nm | Welding, Pipelines | ???? Increases detection of fine cracks |

| Leak Testing | 365nm | Storage Tanks, Valves | ????? Pinpoints even small leaks |

| Radiographic Testing (RT) | 365nm | Pressure Vessels, Piping | ??? Assists in marker visibility |

| Visual Inspection (VT) | 365nm | Surface Defect Detection | ???? Improves detection with UV-sensitive paints |

4. Key NDT Methods Explained

a. Fluorescent Penetrant Testing (FPT)

- Purpose: Detects surface cracks, seams, or porosity.

- Process: A fluorescent dye is applied to the surface, which penetrates cracks. Excess dye is removed, and a developer is applied to draw the dye out of defects. A UV flashlight then illuminates the area, revealing cracks as bright fluorescent lines.

- Advantages: High sensitivity and ability to detect fine cracks.

- Recommended UV Flashlight: TANK007 K9-A5 with 365nm wavelength for clear indications.

b. Magnetic Particle Inspection (MPI)

- Purpose: Identifies surface and near-surface flaws in ferrous materials.

- Process: A fluorescent magnetic powder is applied to a magnetized object. Defects disturb the magnetic field, causing particles to accumulate at flaw sites. UV flashlights highlight these accumulations.

- Advantages: Effective for weld inspections and pipelines.

- Recommended UV Flashlight: TANK007 UVC31 with high power for larger areas.

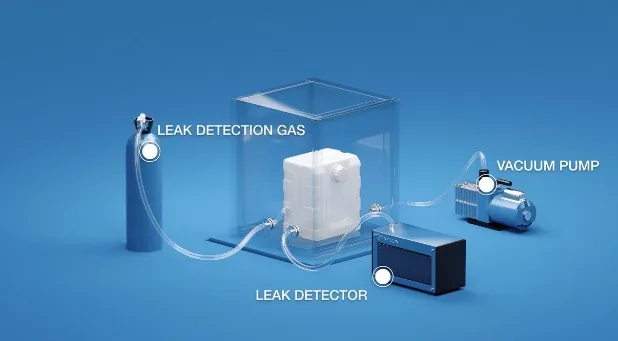

c. Leak Testing

- Purpose: Detects leaks in sealed systems like pipelines and tanks.

- Process: Fluorescent dyes are added to the system’s fluid. A UV flashlight is used to detect any traces of the dye leaking from the system.

- Advantages: Highly sensitive and precise.

- Recommended UV Flashlight: TANK007 UV01 for its portability and effectiveness in small-scale inspections.

5. Comparison of UV Flashlight Models for NDT

| Model | Wavelength | Power Source | Best For | Price Range |

|---|---|---|---|---|

| TANK007 K9-A5 | 365nm | USB Rechargeable | FPT and MPI (Mid-sized areas) | $30–$50 |

| TANK007 UV01 | 365nm | 1 AAA Battery | Leak Testing, Portable Inspections | $15–$25 |

| TANK007 UVC31 | 365nm | 18650 Rechargeable Battery | Large-scale MPI and Professional Use | $50–$70 |

6. Advantages of Using UV Flashlights in NDT

- Enhanced Detection: Makes fluorescent indications highly visible.

- Efficiency: Speeds up inspections with clear and bright indications.

- Safety: Allows detection without damaging the material.

- Versatility: Suitable for various NDT methods like FPT, MPI, and leak testing.

7. Tips for Choosing the Right UV Flashlight for NDT

- Wavelength: Ensure it is 365nm for optimal fluorescence.

- Power Source: Choose USB rechargeable for frequent use or battery-powered for occasional use.

- Brightness: Select higher lumens for large-scale or professional inspections.

8. Summary: Why Choose TANK007 for NDT?

- Specialized UV Flashlights: Designed specifically for NDT applications.

- Durability: Built with aircraft-grade aluminum and waterproof ratings.

- Cost-Effective: Offers models suitable for both professionals and occasional users.

Final Tip:

Choose TANK007 K9-A5 for balanced power, UV01 for budget and portability, and UVC31 for maximum power and professional use.