When it comes to Non-Destructive Testing (NDT), UV flashlights are critical tools for identifying flaws and ensuring material integrity. The two main types of UV flashlights available are LED UV flashlights and traditional bulb UV flashlights. This article explores their features, advantages, disadvantages, and applications, helping you choose the right one for your needs.

Introduction to NDT UV Flashlights

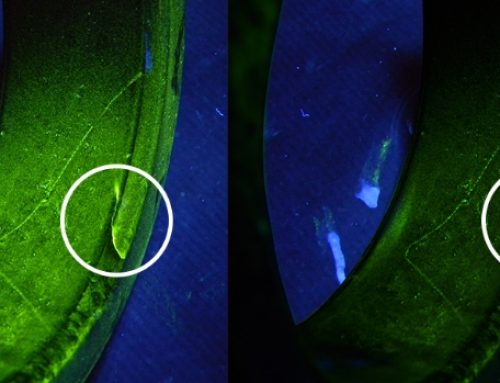

UV flashlights in NDT work by illuminating a surface with ultraviolet light to highlight defects when used with fluorescent penetrants or magnetic particles. The choice between LED and traditional bulb flashlights can significantly impact inspection efficiency and accuracy.

Key Features of LED and Traditional Bulb UV Flashlights

| Feature | LED UV Flashlights | Traditional Bulb UV Flashlights |

|---|---|---|

| Light Source | Light-emitting diodes (LEDs) with a precise wavelength. | Mercury vapor or fluorescent bulbs. |

| Wavelength Stability | Highly stable and consistent. | May vary as the bulb ages or due to temperature changes. |

| Lifespan | Up to 50,000 hours. | 1,000-2,000 hours on average. |

| Energy Efficiency | Highly energy-efficient, consuming less power. | Consumes more power, generating significant heat. |

| Durability | Shockproof and robust design. | Fragile, prone to damage from impacts. |

| Cost | Higher initial cost but lower long-term costs. | Lower upfront cost but higher maintenance expenses. |

Advantages and Disadvantages

LED UV Flashlights

Advantages:

- Efficiency: Consumes less energy, reducing battery usage.

- Lifespan: Longer operational life, minimizing replacement frequency.

- Portability: Compact and lightweight for field inspections.

- Performance: Stable UV output, ensuring consistent inspection results.

Disadvantages:

- Higher upfront cost compared to traditional bulb flashlights.

- Limited to specific wavelengths, typically around 365nm.

Traditional Bulb UV Flashlights

Advantages:

- Lower initial cost, making them accessible for budget-constrained operations.

- Broad-spectrum UV light, suitable for diverse applications.

Disadvantages:

- Shorter lifespan, requiring frequent bulb replacements.

- Bulky and less portable.

- Emits more heat, potentially impacting user comfort and safety.

Applications of LED vs. Traditional Bulb UV Flashlights

| Industry | Preferred Flashlight | Reason |

|---|---|---|

| Aerospace | LED UV Flashlight | Consistent results in critical inspections. |

| Automotive | LED UV Flashlight | Portability and durability for on-site checks. |

| Oil & Gas | LED UV Flashlight | Reliable in harsh environments. |

| Education/Training | Traditional Bulb UV Flashlight | Lower cost for non-intensive use. |

| General Inspection | Depends on budget and needs | Budget may favor traditional; precision favors LED. |

Performance Comparison: LED vs. Traditional Bulb

| Metric | LED UV Flashlight | Traditional Bulb UV Flashlight |

|---|---|---|

| UV Intensity | High and consistent. | May decrease over time. |

| Heat Emission | Minimal, safe for prolonged use. | Significant, can be uncomfortable. |

| Inspection Area | Focused, precise beams. | Broader, less concentrated light. |

| Cost Efficiency | High over the long term. | High maintenance and operating costs. |

| Eco-Friendliness | Environmentally friendly. | Contains hazardous mercury. |

Case Study: Tank007 UVC31-NDT

The Tank007 UVC31-NDT UV flashlight leverages advanced LED technology for professional-grade NDT inspections:

- Wavelength: Stable 365nm UV output for reliable defect detection.

- Lifespan: Over 50,000 hours of operation, reducing long-term costs.

- Durability: Shockproof and water-resistant, ideal for industrial use.

Learn more about Tank007 UVC31-NDT here.

Tips for Selecting the Right UV Flashlight for NDT

- Determine Your Budget: LED flashlights are cost-effective over time but require higher upfront investment.

- Assess Durability Needs: For fieldwork, choose a rugged, shockproof model.

- Prioritize Consistency: LED flashlights ensure stable UV output for precise results.

- Consider Applications: For large-scale inspections, traditional bulbs may provide broader coverage, but LEDs excel in precision tasks.

Conclusion

Both LED and traditional bulb UV flashlights have their merits in NDT. While LED UV flashlights are preferred for their efficiency, durability, and precision, traditional bulb UV flashlights can be suitable for budget-friendly or broad-spectrum applications. For professionals seeking reliability and long-term value, investing in a high-quality LED model like the Tank007 UVC31-NDT is highly recommended.

By understanding the key differences and aligning them with your specific needs, you can ensure optimal inspection performance and cost-efficiency.