Introduction

UV curing resin is widely used in industries such as electronics, coatings, adhesives, and 3D printing. UV light plays a critical role in initiating the chemical reactions necessary for resin hardening, offering a fast and efficient curing process.

1. The Science Behind UV Resin Curing

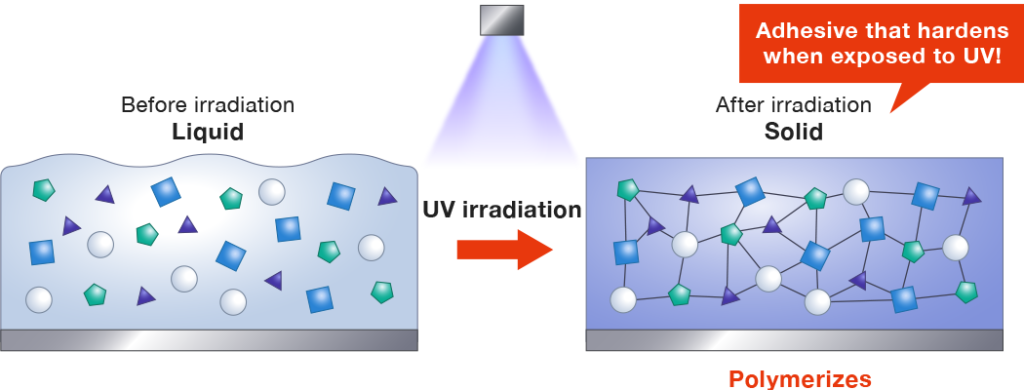

UV resin curing is a photochemical process where ultraviolet (UV) light initiates polymerization, transforming liquid resin into a solid state.

| Component | Function |

|---|---|

| Photoinitiator | Absorbs UV light and breaks down into reactive radicals. |

| Oligomers and Monomers | Serve as the primary building blocks of the cured polymer. |

| Additives | Improve the physical and chemical properties of the cured resin. |

Chemical Reaction:

- When UV light hits the photoinitiators in the resin, it breaks their chemical bonds, releasing free radicals.

- These radicals trigger cross-linking between monomers and oligomers, forming a durable polymer network.

2. Key Factors Influencing UV Resin Curing

Several factors affect the efficiency and quality of UV curing:

| Factor | Description | Impact on Curing |

|---|---|---|

| Wavelength | UV light wavelength (typically 365nm or 405nm) must match the photoinitiator’s absorption spectrum. | Proper wavelength ensures complete curing. |

| Light Intensity | The power of the UV light source. | Higher intensity accelerates curing but may cause overheating. |

| Exposure Time | Duration of UV light exposure. | Insufficient time leads to incomplete curing. |

| Resin Thickness | Thickness of the resin layer. | Thicker layers require longer curing times. |

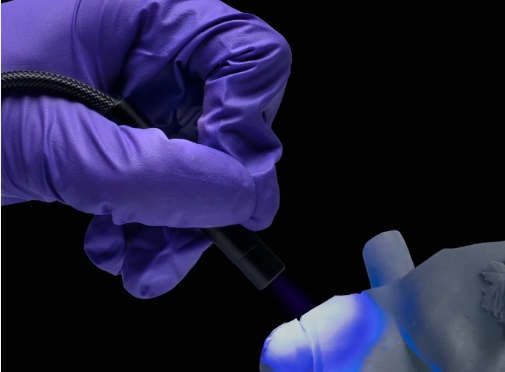

3. Step-by-Step UV Resin Curing Process

- Preparation: Ensure the resin is evenly applied on the desired surface.

- Positioning: Place the UV light source at the recommended distance from the resin surface.

- Exposure: Expose the resin to UV light for the specified duration.

- Cooling: Allow the cured resin to cool to prevent warping or cracking.

- Inspection: Check for uncured spots and re-expose if necessary.

| Step | Key Action | Why It Matters |

|---|---|---|

| 1 | Proper resin application | Ensures uniform curing. |

| 2 | Correct UV light positioning | Prevents uneven curing. |

| 3 | Adequate exposure time | Achieves full polymerization. |

| 4 | Cooling phase | Reduces thermal stress. |

| 5 | Final inspection | Ensures product quality. |

4. Comparison: UV Resin Curing vs. Traditional Heat Curing

| Criteria | UV Resin Curing | Traditional Heat Curing |

|---|---|---|

| Curing Time | Fast (seconds to minutes) | Slow (hours) |

| Energy Consumption | Lower | Higher |

| Precision | High precision for thin layers | Less precise for detailed work |

| Environmental Impact | Reduced emissions | Higher emissions |

| Application Scope | Ideal for electronics, coatings, and adhesives | Better for bulk curing processes |

Conclusion: UV curing is significantly faster, more energy-efficient, and more precise compared to traditional heat curing methods.

5. Common Issues and Troubleshooting During UV Resin Curing

| Issue | Cause | Solution |

|---|---|---|

| Sticky Surface | Insufficient UV exposure or incorrect wavelength. | Increase exposure time or use the correct UV light source. |

| Uneven Curing | Improper light positioning or resin application. | Adjust light placement and ensure even resin application. |

| Overheating | Excessive light intensity or prolonged exposure. | Reduce UV light intensity or limit exposure duration. |

6. Safety Precautions When Using UV Light for Resin Curing

- Wear UV-protective glasses and gloves.

- Avoid direct skin or eye exposure to UV light.

- Use proper ventilation to prevent inhalation of resin fumes.

- Follow manufacturer guidelines for resin and UV equipment.

7. Final Thoughts

Understanding how UV light interacts with resin during curing is essential for achieving consistent, high-quality results. By controlling factors like wavelength, intensity, and exposure time, you can optimize the curing process for a variety of applications. Whether you are working on industrial projects or small DIY crafts, mastering UV resin curing will ensure professional outcomes.

By implementing these insights, businesses and hobbyists can make the most of UV light technology in resin curing processes.