UV flashlights have revolutionized resin curing for both professionals and DIY enthusiasts. While they serve the same basic purpose, the approaches differ in terms of tools, techniques, and results. This guide explores the key distinctions between professional and DIY resin curing with UV flashlights, offering insights to help you choose the best approach for your needs.

Key Differences Between Professional and DIY Resin Curing

| Aspect | Professional Resin Curing | DIY Resin Curing |

|---|---|---|

| Equipment | High-grade UV flashlights with precise wavelength (e.g., 365nm). | Budget-friendly UV flashlights (often 395nm). |

| Applications | Commercial-grade projects like jewelry, coatings, and signage. | Hobbyist projects like small crafts, keychains, or repairs. |

| Curing Speed | Faster due to optimized tools and techniques. | Slower, especially with lower-powered flashlights. |

| Resin Types | Often uses industrial-grade UV-sensitive resin. | Commonly uses hobbyist-grade resin. |

| Results | Durable, professional finishes. | Satisfactory but may lack polish and longevity. |

| Cost | Higher initial investment. | Lower cost, accessible to beginners. |

| Skill Level | Requires expertise and experience. | Beginner-friendly with minimal learning curve. |

What Professionals Look For in a UV Flashlight

- Wavelength:

- 365nm UV flashlights are standard for professional curing, offering pure UV output for precise curing.

- Example: The Tank007 AA02 UV Flashlight, designed for professional use, provides accurate and even curing.

- Power Output:

- High wattage (e.g., 3W or more) ensures faster and more efficient curing, ideal for large-scale or commercial projects.

- Durability:

- Sturdy materials and longer battery life ensure reliability during extended use.

Why DIY Enthusiasts Choose UV Flashlights

- Affordability:

- Budget-friendly options with wavelengths around 395nm are common for casual users.

- Ease of Use:

- Portable, battery-operated devices allow for flexibility in crafting spaces.

- Creative Freedom:

- DIYers enjoy experimenting with designs without worrying about commercial-grade perfection.

Comparison of Popular UV Flashlights

| Model | Wavelength | Power Output | Best For | Price Range |

|---|---|---|---|---|

| Tank007 AA02 | 365nm | 3W | Professional resin curing. | $$ |

| Generic Budget UV Flashlight | 395nm | 1-2W | DIY projects and small crafts. | $ |

| Tank007 High Power NDT Flashlight | 365nm | 5W | Industrial and heavy-duty curing. | $$$ |

Key Considerations for Both Professionals and DIYers

- Resin Compatibility:

- Always ensure your resin is UV-sensitive and matches the flashlight’s wavelength.

- Layer Thickness:

- Thin layers cure faster and more evenly. For thick projects, use a step-by-step curing process.

- Safety Precautions:

- Wear UV-protective glasses and gloves to shield your eyes and skin from harmful UV exposure.

- Work Environment:

- Use in a controlled, low-light setting to enhance the UV light’s effectiveness.

Case Studies: Professional vs. DIY Projects

Professional Use: Jewelry Manufacturing

A jewelry artist used the Tank007 AA02 flashlight for curing intricate resin pendants. The 365nm wavelength ensured:

- Precise curing in under 30 seconds.

- A crystal-clear, bubble-free finish.

- Long-lasting durability, meeting commercial quality standards.

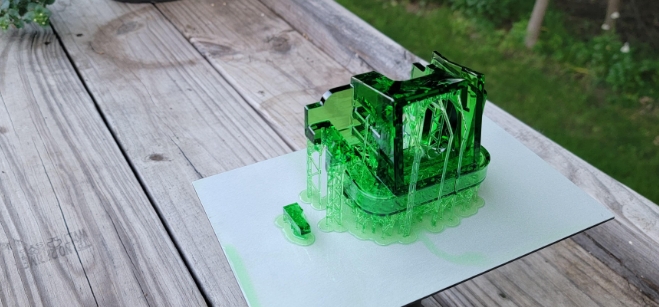

DIY Use: Home Decor Crafts

A hobbyist used a 395nm flashlight for crafting resin coasters. The process:

- Took longer (2-3 minutes per layer).

- Produced functional but less refined results.

- Was cost-effective and fun for personal projects.

When to Choose Professional vs. DIY Resin Curing

| Scenario | Recommended Approach | Reason |

|---|---|---|

| Creating custom jewelry or signage. | Professional | Requires precision and a flawless finish. |

| Making gifts or personal crafts. | DIY | Cost-effective and adequate for casual use. |

| Scaling up for a business. | Professional | High efficiency and consistent quality needed. |

| Learning resin crafting as a hobby. | DIY | Beginner-friendly with minimal investment. |

Conclusion

Both professional and DIY resin curing with UV flashlights have their advantages. while DIYers enjoy the affordability and creativity of budget-friendly options.

By understanding your goals and the available tools, you can achieve the best outcomes for your resin curing projects. Whether you’re a seasoned professional or a creative hobbyist, UV flashlights open up endless possibilities for innovation and artistry.