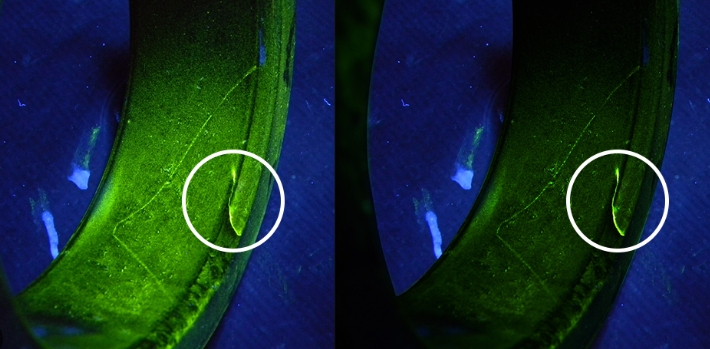

Non-Destructive Testing (NDT) relies on UV flashlights to detect flaws and imperfections in materials without causing damage. To ensure reliable performance, it’s crucial for NDT UV flashlights to meet industry standards and certifications. This article delves into these standards, explaining their significance, requirements, and what to look for when choosing a certified flashlight.

Importance of Standards in NDT UV Flashlights

Adherence to standards ensures:

- Consistent Performance: Guarantees that the flashlight delivers stable UV output at the specified wavelength.

- Reliability: Reduces the risk of missed flaws due to inadequate light quality.

- Safety Compliance: Ensures user safety during prolonged exposure.

- Industry Approval: Meets requirements for use in regulated industries like aerospace, automotive, and oil & gas.

Key Standards and Certifications

| Standard/Certification | Organization | Purpose | Key Requirements |

|---|---|---|---|

| ASTM E3022 | ASTM International | Specifies performance requirements for UV LED lamps used in NDT. | Minimum UV-A intensity, uniform beam distribution, and absence of visible light. |

| ISO 3059 | International Organization for Standardization | Defines requirements for viewing conditions in fluorescent penetrant and magnetic particle testing. | Ambient light levels, UV-A intensity at the workpiece, and eye safety considerations. |

| NADCAP | National Aerospace and Defense Contractors Accreditation Program | Establishes quality assurance standards for aerospace testing. | Certification of UV-A sources, traceability, and calibration procedures. |

| EN 1956 | European Standards (EN) | Specifies safety and performance criteria for UV lamps in penetrant testing. | UV intensity, uniformity, and permissible leakage of visible light. |

| CE Marking | European Union | Certifies that the product meets EU safety, health, and environmental protection standards. | Electrical safety, UV emission compliance, and labeling requirements. |

Detailed Comparison of Standards

| Feature | ASTM E3022 | ISO 3059 | NADCAP | EN 1956 | CE Marking |

|---|---|---|---|---|---|

| UV-A Intensity Range | 1,000–10,000 μW/cm2 | Minimum of 1,000 μW/cm2 | ≥1,200 μW/cm2 | ≥1,000 μW/cm2 | Meets EU safety norms. |

| Visible Light Leakage | ≤20 lux | ≤20 lux | ≤20 lux | ≤20 lux | Varies by application. |

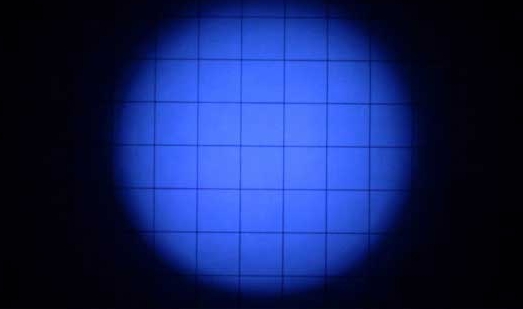

| Beam Uniformity | Required | Not specified | Required | Required | Not specified. |

| Calibration Frequency | Annually recommended | Per user setup | Annually required | Annually required | Not applicable. |

| Industry Application | General NDT | Aerospace | Aerospace | General NDT | Cross-industry. |

Features of Certified NDT UV Flashlights

- UV-A Intensity: Certified flashlights provide precise UV-A output (365nm), ensuring adequate fluorescence of testing materials.

- Beam Uniformity: Reduces the risk of undetected defects in the inspection area.

- Durability: Rugged designs that withstand harsh industrial environments.

- Traceability: Certified models often come with serialized components for calibration tracking.

Tank007 Certified NDT UV Flashlights

Tank007 UVC31-NDT

- Compliance: ASTM E3022, ISO 3059.

- Specifications:

- Wavelength: 365nm with minimal visible light leakage.

- Intensity: Adjustable UV-A output for versatile applications.

- Build: Rugged and waterproof, designed for industrial environments.

- Certifications: CE marking, ensuring compliance with EU safety norms.

Learn more about the Tank007 UVC31-NDT here.

Checklist for Choosing a Certified UV Flashlight

- Check the Wavelength: Ensure it emits UV-A light (365nm) with minimal visible light.

- Verify Compliance: Look for certifications like ASTM E3022, ISO 3059, or EN 1956.

- Beam Uniformity: Ensure uniform light distribution for accurate inspections.

- Durability and Portability: Rugged, lightweight designs for easy handling.

- Calibration Support: Availability of calibration services or in-built calibration tools.

Benefits of Using Certified NDT UV Flashlights

- Enhanced Accuracy: Precise UV-A output ensures reliable flaw detection.

- Compliance with Regulations: Avoid penalties in regulated industries by using certified equipment.

- Improved Safety: Reduced exposure to harmful UV or visible light.

- Cost-Efficiency: Certified flashlights last longer and require minimal maintenance.

Conclusion

Understanding and adhering to NDT standards like ASTM E3022 and ISO 3059 is critical for ensuring the quality, reliability, and safety of UV flashlights. Certified flashlights, such as the Tank007 UVC31-NDT, offer unparalleled performance, making them a valuable investment for professionals across industries.

By selecting a certified flashlight, you not only comply with industry regulations but also enhance inspection efficiency and accuracy, ultimately safeguarding material integrity.