The post Step-by-Step Guide to Using NDT UV Flashlights for Fluorescent Testing appeared first on Tank007.

]]>Non-Destructive Testing (NDT) using UV flashlights plays a critical role in detecting surface and subsurface defects in industrial materials without causing damage. This guide provides a step-by-step process for effectively using NDT UV flashlights in fluorescent testing, highlighting best practices, safety measures, and technical details.

1. Understanding Fluorescent Testing in NDT

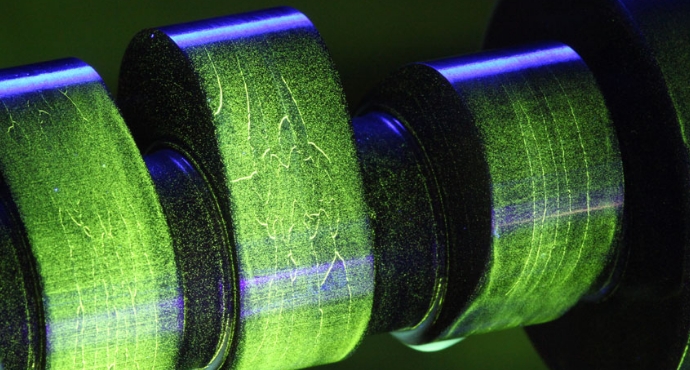

Fluorescent Testing is a method where materials are inspected under ultraviolet (UV) light after being coated with a fluorescent dye penetrant. When exposed to UV light, these dyes emit bright fluorescent colors, revealing cracks, fractures, or other defects.

Key Advantages:

- Non-invasive testing method.

- Accurate detection of surface and near-surface defects.

- Applicable in various industries (Aerospace, Automotive, Manufacturing).

2. Equipment Required for Fluorescent Testing

| Equipment | Description |

|---|---|

| NDT UV Flashlight | High-intensity UV light source (365 nm). |

| Fluorescent Dye Penetrant | Liquid dye for defect highlighting. |

| Cleaner/Remover | Removes excess penetrant. |

| Developer Spray | Enhances defect visibility. |

| Safety Gear | UV goggles, gloves, protective clothing. |

3. Step-by-Step Guide to Using NDT UV Flashlights

Step 1: Surface Preparation

- Objective: Ensure the surface is clean and free from contaminants.

- Actions:

- Use a cleaner to remove oil, grease, and dust.

- Ensure the surface is dry before applying the dye.

Step 2: Apply Fluorescent Dye Penetrant

- Objective: Allow the dye to penetrate surface defects.

- Actions:

- Evenly apply the fluorescent dye on the surface.

- Let it sit for the recommended dwell time (usually 10–30 minutes).

Step 3: Remove Excess Penetrant

- Objective: Avoid background fluorescence that could obscure results.

- Actions:

- Wipe off excess penetrant using a clean cloth.

- Avoid over-cleaning, as it may remove penetrant from defects.

Step 4: Apply Developer

- Objective: Draw penetrant from defects to the surface.

- Actions:

- Spray developer evenly over the surface.

- Allow sufficient time for the developer to act (5–10 minutes).

Step 5: UV Light Inspection

- Objective: Identify and evaluate defects under UV light.

- Actions:

- Darken the inspection area to reduce ambient light.

- Turn on the NDT UV flashlight (365 nm wavelength).

- Scan the surface systematically.

- Look for bright fluorescent indications that suggest cracks or defects.

Step 6: Record and Analyze Findings

- Objective: Document defects for reporting and analysis.

- Actions:

- Photograph and mark detected defects.

- Record the type, size, and location of each defect.

4. Comparison of NDT UV Flashlights vs. Standard Flashlights

| Feature | NDT UV Flashlight | Standard Flashlight |

|---|---|---|

| Wavelength | 365 nm (optimal for NDT) | 400+ nm (ineffective) |

| Light Intensity | High-intensity UV output | General illumination |

| Fluorescence Detection | Yes | No |

| Application | Industrial inspections | General-purpose lighting |

5. Safety Precautions

- Always wear UV-blocking goggles to protect your eyes.

- Avoid direct skin exposure to UV light for prolonged periods.

- Ensure proper ventilation when using chemical penetrants.

- Follow manufacturer guidelines for each piece of equipment.

6. Best Practices for Effective Fluorescent Testing

- Maintain consistent distance between the flashlight and the inspection surface.

- Ensure the UV flashlight has stable power output.

- Regularly calibrate UV equipment for accuracy.

- Use low ambient light conditions during inspections.

7. Real-World Application Example

Scenario: Aerospace Component Testing

- Component: Aircraft engine turbine blades

- Method: Fluorescent penetrant testing with NDT UV flashlight

- Findings: Micro-cracks detected on critical load-bearing areas

- Outcome: Defective parts replaced before critical failure

8. Conclusion

Using NDT UV flashlights for fluorescent testing is an essential and highly effective method for identifying surface and near-surface defects. By following this step-by-step guide, inspectors can ensure consistent results, improved safety, and higher reliability in their inspections.

Explore Tank007’s Range of NDT UV Flashlights for Precision Testing!

The post Step-by-Step Guide to Using NDT UV Flashlights for Fluorescent Testing appeared first on Tank007.

]]>