The post NDT UV Flashlight Maintenance Tips and Tricks appeared first on Tank007.

]]>1. Why Maintenance is Crucial for NDT UV Flashlights

UV flashlights used in NDT are precision instruments. Regular maintenance:

- Ensures Accurate Inspections: Maintains consistent UV output for detecting defects.

- Extends Lifespan: Prevents premature failure of UV LEDs and batteries.

- Reduces Costs: Minimizes repair and replacement expenses.

2. Maintenance Checklist for NDT UV Flashlights

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Inspect Lens and Filters | Before each use | Ensures clear UV transmission. |

| Clean UV Lens | Weekly | Removes dust and contaminants. |

| Check Battery Health | Monthly | Prevents power fluctuations affecting UV output. |

| Test UV Intensity | Quarterly | Ensures compliance with NDT standards. |

| Inspect Casing for Damage | After field inspections | Prevents water or dust ingress. |

| Calibrate UV Output (if applicable) | Annually | Maintains consistent UV intensity for accurate results. |

3. Detailed Maintenance Tips for NDT UV Flashlights

a. Cleaning the UV Lens and Filters

- Why: Dust and oil can reduce UV transmission, causing false or missed indications.

- How:

- Use a soft microfiber cloth slightly dampened with isopropyl alcohol.

- Gently wipe the lens in a circular motion.

- Avoid abrasive materials that could scratch the lens.

- Tip: Avoid touching the lens directly with fingers to prevent smudges.

b. Checking Battery Health

- Why: Power fluctuations can lead to inconsistent UV output.

- How:

- Use a multimeter to check voltage levels. Replace batteries if they drop below 80% of rated capacity.

- For rechargeable models, ensure proper charging cycles and avoid overcharging.

- Tip: Keep spare batteries during long inspections.

c. Inspecting the Casing for Damage

- Why: Cracks or gaps can allow dust or moisture to affect internal components.

- How:

- Check for cracks, especially around seals and buttons.

- Replace O-rings if they appear worn or brittle.

- Tip: Store flashlights in a protective case when not in use.

d. Testing UV Intensity

- Why: UV intensity below the required level may cause false negatives.

- How:

- Use a UV radiometer to measure output at a fixed distance (usually 15 inches).

- Ensure it meets the required NDT standard (often 1,000 μW/cm2).

- Tip: Keep a record of intensity tests for compliance audits.

4. Troubleshooting Common Issues

| Issue | Possible Cause | Solution |

|---|---|---|

| Dim UV Output | Low battery or dirty lens | Replace batteries, clean lens, and check LED connections. |

| Inconsistent UV Beam | Faulty power connection or LED degradation | Inspect wiring, replace damaged LEDs. |

| Flickering Light | Loose battery contacts or damaged switch | Tighten contacts, replace switch if needed. |

| Overheating | Blocked heat vents or prolonged use | Allow to cool, clean vents, reduce continuous usage time. |

| Moisture Inside Casing | Damaged seals or exposure to water | Replace O-rings, dry thoroughly, inspect for cracks. |

5. Comparison: Maintenance of Rechargeable vs. Disposable Battery UV Flashlights

| Aspect | Rechargeable Batteries | Disposable Batteries |

|---|---|---|

| Cost | Higher upfront cost, lower long-term cost | Lower upfront cost, higher long-term cost |

| Maintenance | Requires regular charging and cycle management | Replace batteries when drained, minimal maintenance |

| Lifespan | Longer if properly maintained | Limited by battery availability |

| Environmental Impact | Lower due to reusable nature | Higher due to disposable waste |

| Recommended For | Frequent users and professional inspections | Occasional users and emergency kits |

6. Best Practices for Storing UV Flashlights

- Keep in a Dry Environment: Prevents moisture-related damage.

- Use Protective Cases: Shields against dust and impacts.

- Store Batteries Separately: Reduces risk of corrosion inside the flashlight.

- Avoid Direct Sunlight: Prevents UV LED degradation and battery overheating.

7. Calibration Tips for NDT UV Flashlights

Why: Calibration ensures that UV output remains within standard levels, providing accurate NDT results.

How to Calibrate:

- Use a calibrated UV radiometer.

- Measure UV intensity at a standard distance (typically 15 inches).

- Adjust the flashlight’s settings if it has built-in calibration.

- Record calibration results and keep documentation for compliance.

Tip: Schedule calibration annually or after 500 hours of use.

8. Summary: Key Maintenance Tips

- Clean Regularly: Focus on lenses and filters.

- Test UV Intensity: Use a radiometer quarterly.

- Inspect for Damage: Check casing, seals, and buttons.

- Battery Care: Replace or recharge promptly.

Consistent maintenance not only extends the lifespan of your NDT UV flashlight but also ensures reliable and accurate inspections. Implement these tips to keep your equipment performing at its best!

The post NDT UV Flashlight Maintenance Tips and Tricks appeared first on Tank007.

]]>The post What is an NDT UV Flashlight and How It Works? appeared first on Tank007.

]]>What is an NDT UV Flashlight?

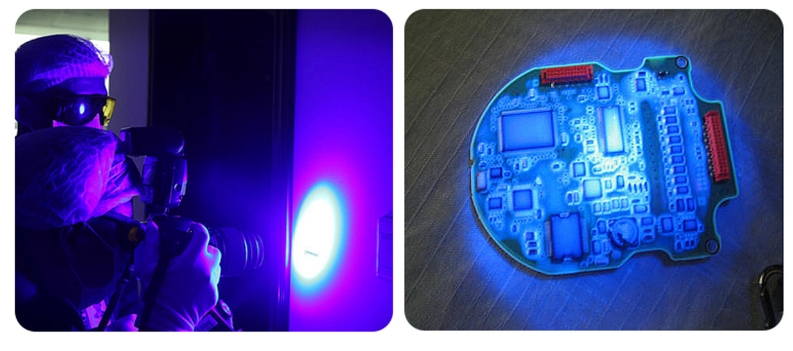

An NDT UV flashlight is a specialized ultraviolet light tool used in fluorescent inspection processes within non-destructive testing. It emits UV-A light in the wavelength range of 320–400 nanometers, which is ideal for activating fluorescent dyes or coatings applied to materials. When these dyes are exposed to UV light, they fluoresce brightly, revealing cracks, leaks, or other imperfections that are invisible to the naked eye.

How Does an NDT UV Flashlight Work?

The working principle of an NDT UV flashlight is based on fluorescence. Here’s a breakdown:

- Surface Preparation: The material surface is cleaned and treated with a fluorescent penetrant or dye.

- Penetrant Application: The dye is applied and allowed to seep into any surface cracks or flaws.

- Excess Removal: Excess dye is removed, leaving only the penetrant in the flaws.

- Inspection with UV Light: The NDT UV flashlight illuminates the surface. Flaws appear as bright fluorescent lines or spots under the UV light.

Applications of NDT UV Flashlights

- Aerospace: Inspection of aircraft parts for fatigue cracks.

- Automotive: Quality control of components like engine blocks.

- Oil and Gas: Pipeline and tank inspection for corrosion or leakage.

- Power Plants: Examination of pressure vessels and turbines.

Key Features of NDT UV Flashlights

| Feature | Description | Importance |

|---|---|---|

| UV Wavelength | 365 nm is the industry standard. | Provides optimal fluorescence of dyes. |

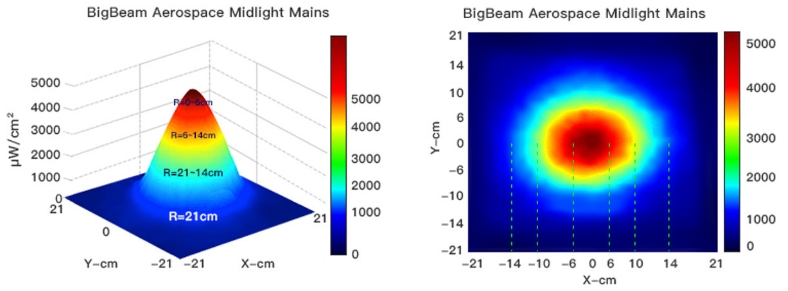

| Beam Uniformity | Consistent UV beam without hotspots. | Ensures even illumination for accurate inspection. |

| Light Intensity | Typically measured in microwatts/cm2. | High intensity ensures better visibility of flaws. |

| Battery Life | Long-lasting rechargeable batteries. | Reduces downtime during inspections. |

| Portability | Compact and lightweight design. | Easy to handle in confined spaces. |

Types of NDT UV Flashlights

| Type | Description | Recommended Use |

|---|---|---|

| Handheld UV Flashlights | Compact and portable with high-intensity UV light. | General NDT inspections in various industries. |

| Stationary UV Lamps | Larger devices for covering broader areas. | Ideal for labs or large-scale inspections. |

| Rechargeable UV Lights | Environmentally friendly, cost-effective models. | Frequent use in remote locations. |

| Waterproof UV Lights | Designed to resist moisture and harsh environments. | Suitable for oil, gas, and marine applications. |

Advantages of Using NDT UV Flashlights

- Non-Invasive: Detects flaws without damaging the material.

- High Sensitivity: Reveals even microscopic defects.

- Cost-Effective: Reduces downtime by identifying issues early.

- Versatile Applications: Can be used across various industries and materials.

How to Choose the Right NDT UV Flashlight?

When selecting an NDT UV flashlight, consider:

- Wavelength Compliance: Ensure it emits UV-A light at 365 nm.

- Intensity Standards: Meets or exceeds ASTM and ISO standards.

- Durability: Built for rugged industrial environments.

- Portability: Lightweight and ergonomic for ease of use.

- Certification: Look for certifications like CE or RoHS for quality assurance.

Conclusion

The NDT UV flashlight is a cornerstone tool in non-destructive testing, enabling professionals to detect imperfections with precision and reliability. By choosing the right flashlight and using it effectively, industries can maintain safety, ensure quality, and minimize operational risks.

Investing in high-quality NDT UV flashlights like those offered by Tank007 can enhance your inspection processes and deliver exceptional results.

The post What is an NDT UV Flashlight and How It Works? appeared first on Tank007.

]]>