UV flashlights are an essential tool in the process of resin curing, a technique commonly used in industries such as jewelry making, arts and crafts, automotive repair, and even dentistry. These specialized flashlights emit ultraviolet (UV) light that activates photoinitiators in resin, leading to a hardening or curing reaction. This article will explore the science behind using UV flashlights for resin curing, how it works, and the factors that influence the curing process.

What is Resin Curing?

Resin curing refers to the process in which liquid resin is transformed into a hard, solid form. This transformation happens when a chemical reaction is triggered by UV light or heat, depending on the type of resin being used. UV resin curing is particularly popular because it offers quick and precise curing, which makes it ideal for applications that require detailed work.

- Photoinitiators: Special chemicals in UV resin that react when exposed to UV light, causing the resin to polymerize and harden.

- Polymerization: The process in which molecules in the resin bond together to form a solid structure.

How Does UV Flashlight Cure Resin?

Step 1: Exposure to UV Light

When UV resin is exposed to ultraviolet light, it reacts with photoinitiators within the resin. This initiates the polymerization process, where the molecules in the resin start bonding together to form a hardened material.

| Photoinitiator | Reaction Under UV Light |

|---|---|

| Benzoin ethers | Causes rapid curing, common in many UV resins. |

| Camphorquinone | Often used in dental applications, reacts with light to harden the resin. |

| Thioxanthone | Used in inks and coatings, leads to hardening when exposed to UV. |

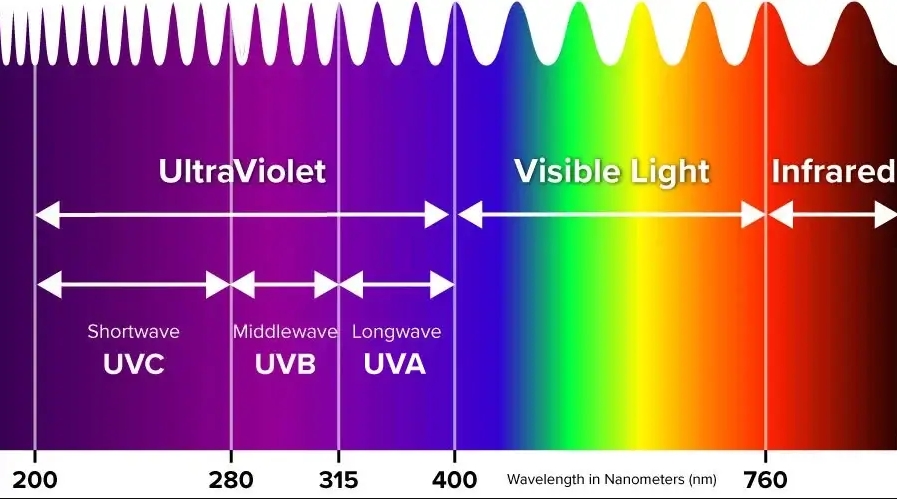

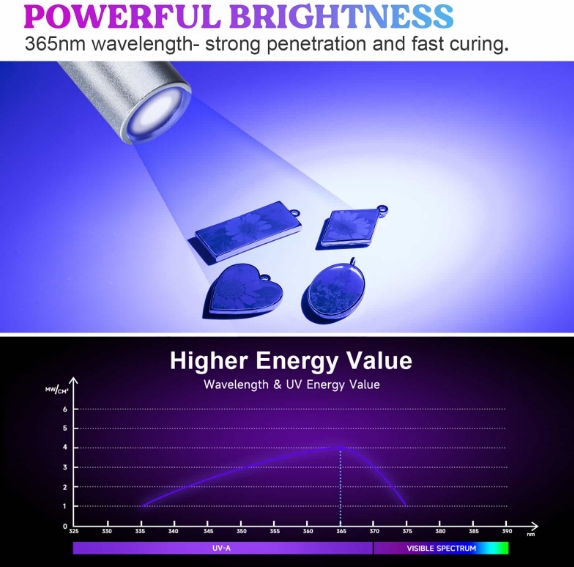

UV light wavelength: For the resin curing process, the wavelength of the UV light typically ranges between 365nm and 405nm. Different wavelengths react with different photoinitiators, which makes selecting the right UV flashlight essential for optimal curing.

Step 2: Polymerization and Hardening

Once the resin is exposed to UV light, the photoinitiators trigger polymerization. This process causes the liquid resin to become hard and durable.

| Wavelength | Resin Curing Effectiveness |

|---|---|

| 365nm | Ideal for deeper curing, suitable for thick resins and professional applications. |

| 405nm | Good for surface curing and faster results, commonly used for thin layers of resin. |

Key Factors in UV Resin Curing with Flashlights

1. Wavelength of the UV Flashlight

The wavelength of the UV flashlight plays a crucial role in determining the effectiveness of resin curing. Flashlights that emit a wavelength of 365nm provide a deeper and more intense curing effect, which is ideal for thick resin layers. 405nm wavelengths are effective for surface curing and are typically used for smaller or thinner resin projects.

- 365nm UV light: Best for curing deep layers and professional-grade resin applications. It provides better penetration into the resin.

- 405nm UV light: Typically used for curing thin layers of resin faster, suitable for DIY projects and small crafts.

| Wavelength | Depth of Curing | Best for |

|---|---|---|

| 365nm | Deeper penetration and longer curing time. | Professional-grade resin, deep applications. |

| 405nm | Surface curing with faster results. | Small-scale applications, quick-drying projects. |

2. UV Flashlight Power (Wattage)

The power output of a UV flashlight is another important factor. Higher wattage results in stronger UV light output, leading to faster curing. However, it is essential to balance power with resin thickness, as very high wattage can cause uneven curing if the resin is too thick.

| Wattage | Effect on Curing |

|---|---|

| 3W-5W | Suitable for general resin curing. |

| 5W-10W | Provides faster curing, ideal for professional use. |

| 10W+ | High power for quick curing of thicker resin layers. |

3. Exposure Time

The curing time depends on several factors, including the type of resin, the UV light intensity, and the resin’s thickness. Generally, thicker resins require longer exposure to UV light. Most UV resins will cure within a few minutes to an hour, depending on these factors.

| Resin Thickness | Exposure Time (at 365nm) |

|---|---|

| Thin Layer | 1-3 minutes |

| Medium Layer | 5-10 minutes |

| Thick Layer | 20-60 minutes |

Advantages of Using UV Flashlight for Resin Curing

- Speed: UV curing can occur in just a few minutes, unlike traditional curing methods that may take hours.

- Precision: With a UV flashlight, you can focus light on specific areas, ensuring precise curing without affecting surrounding surfaces.

- Convenience: Portable and easy to use, making it ideal for small-scale or DIY projects.

- Energy Efficient: UV flashlights consume less power compared to traditional curing ovens, which is especially beneficial for smaller workshops.

How to Choose the Right UV Flashlight for Resin Curing

When selecting a UV flashlight for resin curing, here are some factors to consider:

| Factor | What to Consider |

|---|---|

| Wavelength | Choose 365nm for deeper curing and 405nm for faster surface curing. |

| Power | Higher wattage (5W+) for quicker curing, lower wattage (3W) for precision. |

| Portability | Choose a compact, rechargeable flashlight for DIY or fieldwork. |

| Durability | Look for a flashlight with an aluminum body or impact-resistant design. |

Recommended UV Flashlight for Resin Curing: TANK007 K9A5

For efficient and high-quality resin curing, the TANK007 K9A5 UV Flashlight is a top choice. This flashlight offers:

- 365nm Wavelength: Provides optimal curing depth for a variety of resin types.

- Powerful 5W LED: Ensures fast and even curing for thick resin layers.

- Rechargeable Battery: Convenient and cost-effective, with long-lasting performance.

- Durable and Compact: Perfect for both professionals and hobbyists.

Conclusion

UV flashlights play a vital role in the resin curing process, enabling rapid and precise curing for a wide range of applications. By understanding the science behind UV curing, including the importance of wavelength, power, and exposure time, you can select the right flashlight for your resin projects.