Non-Destructive Testing (NDT) is a vital process in industries like aerospace, automotive, and manufacturing, ensuring material integrity without causing damage. Among the tools used in NDT, the UV flashlight is indispensable for detecting flaws and verifying processes.

What is an NDT UV Flashlight?

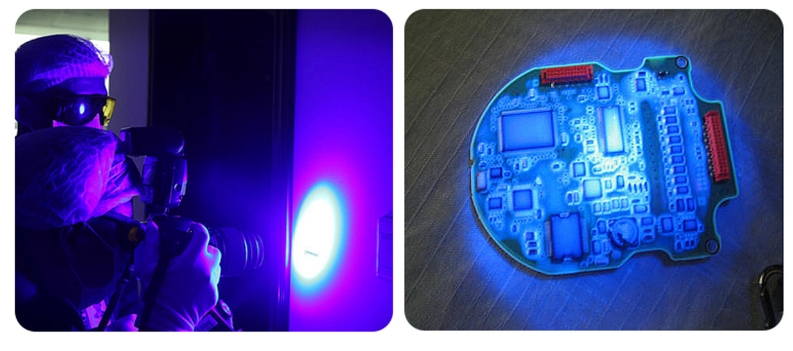

An NDT UV flashlight is a specialized ultraviolet light tool used in fluorescent inspection processes within non-destructive testing. It emits UV-A light in the wavelength range of 320–400 nanometers, which is ideal for activating fluorescent dyes or coatings applied to materials. When these dyes are exposed to UV light, they fluoresce brightly, revealing cracks, leaks, or other imperfections that are invisible to the naked eye.

How Does an NDT UV Flashlight Work?

The working principle of an NDT UV flashlight is based on fluorescence. Here’s a breakdown:

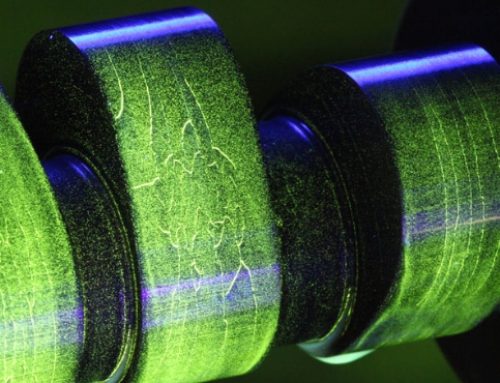

- Surface Preparation: The material surface is cleaned and treated with a fluorescent penetrant or dye.

- Penetrant Application: The dye is applied and allowed to seep into any surface cracks or flaws.

- Excess Removal: Excess dye is removed, leaving only the penetrant in the flaws.

- Inspection with UV Light: The NDT UV flashlight illuminates the surface. Flaws appear as bright fluorescent lines or spots under the UV light.

Applications of NDT UV Flashlights

- Aerospace: Inspection of aircraft parts for fatigue cracks.

- Automotive: Quality control of components like engine blocks.

- Oil and Gas: Pipeline and tank inspection for corrosion or leakage.

- Power Plants: Examination of pressure vessels and turbines.

Key Features of NDT UV Flashlights

| Feature | Description | Importance |

|---|---|---|

| UV Wavelength | 365 nm is the industry standard. | Provides optimal fluorescence of dyes. |

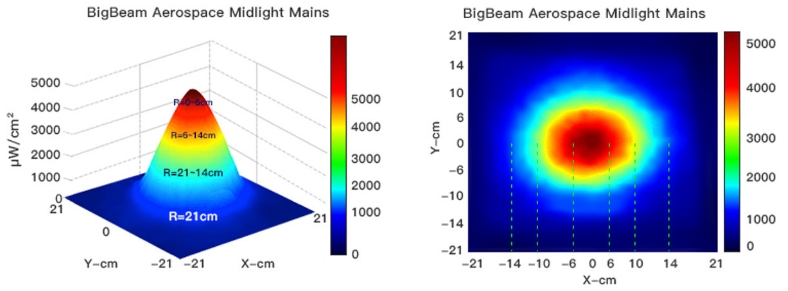

| Beam Uniformity | Consistent UV beam without hotspots. | Ensures even illumination for accurate inspection. |

| Light Intensity | Typically measured in microwatts/cm2. | High intensity ensures better visibility of flaws. |

| Battery Life | Long-lasting rechargeable batteries. | Reduces downtime during inspections. |

| Portability | Compact and lightweight design. | Easy to handle in confined spaces. |

Types of NDT UV Flashlights

| Type | Description | Recommended Use |

|---|---|---|

| Handheld UV Flashlights | Compact and portable with high-intensity UV light. | General NDT inspections in various industries. |

| Stationary UV Lamps | Larger devices for covering broader areas. | Ideal for labs or large-scale inspections. |

| Rechargeable UV Lights | Environmentally friendly, cost-effective models. | Frequent use in remote locations. |

| Waterproof UV Lights | Designed to resist moisture and harsh environments. | Suitable for oil, gas, and marine applications. |

Advantages of Using NDT UV Flashlights

- Non-Invasive: Detects flaws without damaging the material.

- High Sensitivity: Reveals even microscopic defects.

- Cost-Effective: Reduces downtime by identifying issues early.

- Versatile Applications: Can be used across various industries and materials.

How to Choose the Right NDT UV Flashlight?

When selecting an NDT UV flashlight, consider:

- Wavelength Compliance: Ensure it emits UV-A light at 365 nm.

- Intensity Standards: Meets or exceeds ASTM and ISO standards.

- Durability: Built for rugged industrial environments.

- Portability: Lightweight and ergonomic for ease of use.

- Certification: Look for certifications like CE or RoHS for quality assurance.

Conclusion

The NDT UV flashlight is a cornerstone tool in non-destructive testing, enabling professionals to detect imperfections with precision and reliability. By choosing the right flashlight and using it effectively, industries can maintain safety, ensure quality, and minimize operational risks.

Investing in high-quality NDT UV flashlights like those offered by Tank007 can enhance your inspection processes and deliver exceptional results.