LED light source explosion-proof lamps with less energy consumption, high luminous efficiency, long life and environmental protection and other advantages. Such as outdoor landscape lighting, indoor lighting and industrial explosion-proof lighting.

At present, there are still some shortcomings in the performance of white LED lamps. Such as light color deviation and aging.

Take portable LED explosion-proof flashlight as an example. Its life can usually reach five years or longer, but long life does not equal to the stability as always.

With the use of time becomes longer, LED explosion-proof torch luminous luster and stability will decline. So what kind of explosion-proof flashlight is more stable? What new technology can improve the stability of explosion-proof flashlights?

Yellow light single crystal technology can effectively improve the life of LED explosion-proof lamps

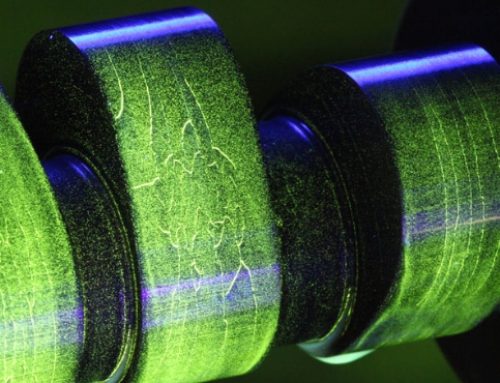

The LED light source technology of LED explosion-proof searchlight is based on combination of blue chip and yellow phosphor.

To produce white light. This kind of white explosion-proof flashlight made by traditional technology is very easy to aging. The high temperature emitted is easy to make the fluorescent powder failure while using a long time.

The intuitive feeling of using explosion-proof flashlight is that the light color turns blue. The brightness drops, and the color temperature tends to cool color.

A new type of yellow single crystal material can slove the problem effectively. It extracted at high temperature of 2000℃.

TANK007 explosion-proof flashlight designers believe that by matching a single crystal material of yellow light on the LED blue chip,

they can produce a stable LED white light. It is worth mentioning that yellow single crystal has the characteristics of high temperature resistance

and good thermal conductivity. Compared with traditional yellow phosphor, yellow single crystal can make LED light color more stable, last longer,

and improve the service life of LED. The LED chip will not produce high temperature due to long-term continuous work. By controlling the composition,

To meet various, it is available to adjust concentration and thickness of the crystal, different intensity of light and color temperature. And makes white LED lights of various lengths and shapes.

of industrial explosion-proof lighting and portable outdoor strong light lighting.

When you make yellow light crystals, you can. In addition, Xiang has developed an alternative material to yellow light powder, yellow fluorescent glass,

which is less durable than yellow light crystal, but costs less and takes less time. Both of which have met market specifications.

Scientific cooperation breaks through traditional technology, making LED lamp production more convenient

Not only invented alternative materials to make it more durable, but also to break through the traditional process. And make them easier and more efficient. To combine with either a yellow powder or a yellow crystal with Current processes for white LEDS require a chip

Making the two together requires AB glue, which is not that durable. So how to use glue to make the process easier? He came up with a new way to “grow” blue chips

on yellow light crystals, is to make the two together, no glue bonding. At present, the process is still under further development.

In addition to break with conventional technology, he developed red crystals. Emit red light makes white leds glow more softly. Only the combination of yellow and blue light produces white light. It is mostly harsh, and adding red light makes it softer and more comfortable, he said.

At present, it is working on how to fuse yellow and red crystals. Using one crystal to create the effect of two, a process is perfect.

TANK007 TX105C USB type C rechargeable firefighting explosion-proof explosion led torch light